An onsite nitrogen generator system produces industrial-grade nitrogen gas on-demand by separating it from ambient air. These onsite nitrogen generator systems eliminate dependence on delivered cylinders or liquid nitrogen, enhancing supply reliability and lowering operating costs. Two primary methods—Pressure Swing Adsorption (PSA) and membrane separation—are commonly used. PSA systems use carbon molecular sieves to adsorb oxygen and other impurities, yielding very high-purity nitrogen (up to 99.999% in many designs). Membrane systems use hollow-fiber membranes that preferentially permeate oxygen and water vapor, supplying nitrogen up to about 99% purity. Both technologies require clean, dry compressed air (typically 7–12 bar inlet pressure and a dryer to about -40 °C dew point) and produce a continuous nitrogen stream at controlled pressure (usually 4–10 bar). Modern onsite nitrogen generators are fully automated, with instrumentation (flow meters, oxygen analyzers, dew-point sensors) to maintain stable output.

PSA Nitrogen Generation Technology

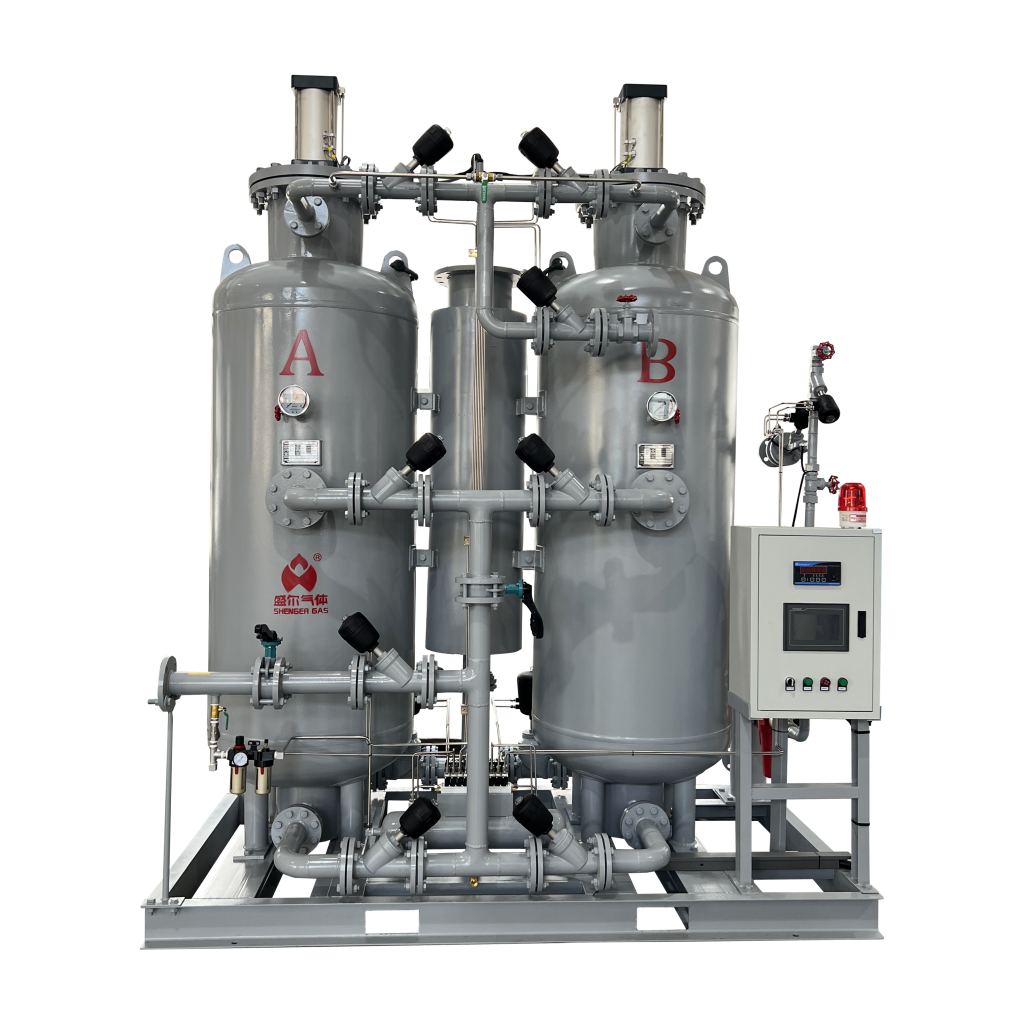

In a PSA onsite nitrogen generator system, compressed air is first pretreated through coalescing filters, carbon filters, and a desiccant or refrigerated dryer to remove oil, dust, and moisture. The clean, dry air is then directed into two alternating adsorption vessels filled with carbon molecular sieve (CMS). At high pressure, oxygen (and trace CO₂ or moisture) preferentially adsorbs onto the CMS, while nitrogen passes through as the product gas. When one vessel becomes saturated with oxygen, the system switches valves so that the second vessel takes over adsorption while the first vessel is depressurized and purged of the adsorbed gases (often using a small fraction of product nitrogen). This cyclic process provides a steady nitrogen flow.

PSA systems can routinely achieve nitrogen purities from about 95% up to 99.999%, covering the full industrial range. Higher pressure and larger adsorbent volumes yield higher purity (at the expense of flow rate). Typical outlet pressures are in the range of 4–10 bar (60–150 psig), though booster compressors can raise purity or pressure further for cylinder filling. The product dew point (dryness) depends on the downstream dryer; many systems provide gas at –40 to –60 °C dew point (with additional desiccants) to protect sensitive applications. PSA units are well-suited for medium to large flow demands (from tens to thousands of normal cubic meters per hour), and designs range from small skid-mounted units to large containerized plants. They require periodic maintenance of valves and replacement of filters, but with proper air treatment the CMS beds can last over 10–20 years.

Membrane Nitrogen Generation Technology

Membrane nitrogen generators offer a simpler, more compact alternative for moderate flow and purity needs in onsite nitrogen generation systems. In these systems, clean compressed air is sent through bundles of hollow-fiber polymer membranes. The membrane material is selectively permeable: small molecules like oxygen, carbon dioxide, and water vapor diffuse through the fiber walls faster than larger nitrogen molecules. As a result, the retentate (core stream) is enriched in nitrogen. Purge air carrying the oxygen is vented as waste.

Membrane systems typically achieve nitrogen purities from about 95% up to ~99% (some specialty membranes approach 99.5% but at low flow). Performance drops rapidly beyond ~98% purity. These generators require less plumbing and no switching valves, making them lightweight and fast to start. Product flow from a membrane unit is very stable and continuous, with minimal pulsation. However, membrane systems are generally intended for low to medium flows (from a few Nm³/hr up to a few hundred Nm³/hr) and lower purities. Outlet pressure is usually up to about 6–8 bar (80–120 psig) directly. The membranes are sensitive to liquid water and oil (like any generator), so air drying to around –20 to –40 °C dew point is recommended to maintain throughput and prevent damage. Membranes gradually “age” and lose throughput over many years, so replacement or refurbishment may be needed after ~5–10 years, whereas PSA adsorbent is relatively stable if not contaminated.

Typical Performance Comparison

The table below summarizes typical specifications for PSA vs. membrane onsite nitrogen generators. These values can vary by manufacturer and design, but illustrate the general differences in purity, flow, pressure, and power:

| Parameter | PSA Nitrogen Generator | Membrane Nitrogen Generator |

|---|---|---|

| Nitrogen purity (%) | 95 – 99.999 | 95 – 99.5 |

| Flow capacity (Nm³/hr) | ~10 – 5,000+ (scalable) | ~1 – 500 (module-based) |

| Inlet pressure (bar) | ~7 – 12 | ~7 – 12 |

| Outlet pressure (bar) | up to ~10 (often 4–8 bar) | up to ~6–8 (often 4–6 bar) |

| Product dew point (°C) | –40 to –80 (with dryer)** | –20 to –40 (with dryer) |

| Power consumption | ~0.2 – 0.3 kW per Nm³/h (95%) | ~0.3 – 0.5 kW per Nm³/h (95%)* |

*Values are representative; actual power use depends on system efficiency, purity and flow requirements. **PSA systems often include additional aftercooling/drying.

Industrial Applications

Steel and Metal Processing: In steel and metal processing, an onsite nitrogen generator system is essential for creating an oxygen-free environment in heat-treating furnaces and metal sintering applications. High-pressure nitrogen is also used in blanketing molten metal to minimize scale formation. Laser cutting and welding often require oxygen-free nitrogen to produce clean edges (especially for stainless steel and aluminum). Onsite generators supply a continuous nitrogen stream for quench tanks, powder metallurgy, and metal sintering, all of which benefit from an oxygen-free atmosphere. PSA systems (with purities >99.5%) are common for ultra-clean applications like precision laser cutting or bright annealing, while membranes can serve general blanketing.

Electronics and Semiconductor Manufacturing: For electronics and semiconductor manufacturing, onsite nitrogen generator systems offer high-purity nitrogen that is crucial for soldering, semiconductor lithography, and cleaning equipment. Nitrogen blanketing in reflow ovens and soldering equipment prevents oxide formation on circuit joints, improving yield. In semiconductor fabs, N₂ purges are used in etch and deposition tools to avoid contamination. Semiconductor and PCB assembly typically require 99.99%+ N₂; onsite PSA generators provide these high purities with continuous monitoring. Even lower-purity membrane systems can be used for simpler tasks like cleaning or drying equipment, where 95–98% N₂ is adequate. In soldering, providing an inert N₂ stream leads to stronger solder joints and higher product reliability by eliminating the oxygen-related defects.

Food and Beverage: Nitrogen is a food-safe inert gas used to extend shelf life and ensure quality. Onsite generators fill bags of snack foods (potato chips, nuts, etc.) with nitrogen to flush out oxygen and prevent rancidity. In liquid food processing and packaging, nitrogen blanketing of tanks and bottle headspaces prevents oxidation of oils, coffee, juices, and wine. For example, wineries use N₂ to purge air from fermentation and bottling lines, preserving flavors and color. Beverage producers use nitrogen for beer dispensing (nitro-beers) and to maintain purge conditions in tanks. Membrane generators are often sufficient here (85–98% N₂), but PSA may be chosen where very low oxygen is critical (e.g. for canned foods or pharmaceutical-grade ingredients). The dry, oxygen-free nitrogen also improves drying processes (bottles, cans, equipment) due to low dew point.

Petrochemicals and Chemicals: Refineries and chemical plants rely on nitrogen for safety and process control. Onsite N₂ generators are used for tank and vessel blanketing (preventing flammable atmospheres in storage tanks), pipeline purging (removing oxygen during commissioning), and catalyst protection. In petrochemical processing, nitrogen is used to inert storage tanks holding hydrocarbons, as well as to displace air in reactors during maintenance. Offshore platforms and remote oil wells often incorporate nitrogen generators to maintain local inert gas supplies, eliminating reliance on shipped cylinders. Typical purity needs are moderate (95–98% N₂) for bulk blanket, but some lab-scale or analytical needs in the plant may require >99.9%. PSA systems (often with integral oxygen analyzers) ensure purity for safety-critical applications, whereas membrane units can economically handle large purge flows for pipelines or flare stacks.

- Key industry uses: Blanketing/reactor purging (chemicals), fire system inerting (tire plants, chemical warehouses), packaging inerting (chemical drums), and lab gas (biotech, pharma manufacturing).

Regional Considerations

- Europe: European industries (German auto plants, French food producers, Scandinavian metalworks) adopt onsite N₂ generation to meet stringent efficiency and environmental standards. EU regulations on transportation and emissions give incentives to reduce heavy gas deliveries; on-site generation cuts CO₂ from tanker trucks. Manufacturers in Europe emphasize certified systems (PED, CE) and often integrate smart controls for Industry 4.0 integration. The mature compressed-air infrastructure and focus on energy recovery (e.g. waste heat from compressors) enhance the attractiveness of generators. Cold-climate countries ensure equipment is rated for subzero ambient in winter.

- Southeast Asia: Rapid growth in electronics, automotive, and food processing in countries like Malaysia, Thailand, Vietnam, and Singapore is driving nitrogen demand. Onsite generators are gaining traction as factory-supplied gas lines are less common, and import logistics can be complex. In hot, humid climates, robust air drying and condensate management are critical. Many manufacturers prefer PSA systems for high-capacity and high-purity needs (e.g. semiconductor fabs in Malaysia), while smaller food and beverage firms opt for compact membrane units to save space and cost. Regional suppliers often tailor systems for 50 Hz power and tropical filtration standards, with corrosion-resistant materials for coastal or tropical environments.

- Middle East: The oil & gas and petrochemical sectors of the Middle East (Gulf Cooperation Council countries, Iran, Iraq) require massive volumes of nitrogen for refining and offshore operations. Onsite generators are essential in remote desert or marine sites where gas logistics are challenging. Systems must withstand high ambient temperatures (often >45 °C) and dusty conditions; hence, prefilters and coolers are emphasized. Nitrogen blanketing of fuel depots, LNG tanker pressurization, and chemical plant purging are common uses. In large-scale desalination and power plants, on-site N₂ also supports control systems. While membrane units are used for simpler inerting jobs, PSA generators dominate where ultra-high purity or very high flow (several thousand Nm³/h) is needed. Energy costs are relatively low in the region, but reliability and turnkey integration (often including generators and compressed air packages) are key selling points.

Onsite Generation vs. Delivered Supply

- Continuous supply and control: Onsite systems deliver nitrogen on-demand with consistent purity and pressure. Unlike cylinders or tanks, generators eliminate delivery delays and storage constraints. Inline oxygen sensors and dew-point monitors ensure process requirements are met at all times.

- Cost efficiency: Over the long term, onsite generation can drastically cut operational costs. Companies avoid the recurring expense of purchasing and transporting gas. Energy cost per Nm³ of N₂ is typically lower than the market rate for bulk nitrogen, especially for high-demand sites. For example, modern PSA generators can consume on the order of 0.2–0.3 kW per Nm³ (95% purity); this often undercuts liquid N₂’s total delivered cost.

- Safety and logistics: Onsite N₂ reduces safety risks associated with handling and storing cylinders or cryogenic tanks. It also frees up space previously used for gas inventory. In remote or offshore locations, a self-contained generator avoids the hazards and carbon footprint of frequent supply shipments.

- Scalability and flexibility: Generators can be sized to exact flow needs and expanded modularly if demand grows. PSA systems can often be paralleled or banked for redundancy. In contrast, pre-purchased tanks cannot be easily adjusted to changing requirements.

- Lower carbon footprint: Eliminating road or sea transport of nitrogen reduces greenhouse gas emissions. This aligns with sustainability goals, which is increasingly important in regions like Europe. Even accounting for electricity use, onsite generation’s lifecycle impact can be lower than delivered gas, particularly if renewable electricity is used.

Limitations and Considerations

- Capital cost: A drawback is the initial investment for the generator and supporting equipment (compressors, dryers). Small operations with low N₂ usage may not justify the upfront expense. Careful economic analysis (calculating payback time vs cylinder rental or bulk deliveries) is needed.

- Energy consumption: Onsite generation requires significant electricity (mainly for air compression). Systems must be sized to optimize energy use versus purity. In areas where power is very expensive or unreliable, the operating cost can be a concern.

- Maintenance: PSA units have valve systems and adsorbent beds that require scheduled servicing (filter changes, occasional sieve replacement). Membranes slowly degrade over time. Both technologies need high-quality compressed air (oil-free, very low moisture); failure of pretreatment can damage the generator. Companies must commit to proper maintenance and monitoring.

- Maximum purity: For applications needing ultra-high purity (>99.9999%) or extremely low ppm oxygen, specialized cylinder or liquid nitrogen with purification (or more complex generator setups) may still be needed. However, for most industrial applications, generators suffice.

- Space and environment: Although compact relative to bulk plants, generators and their air compressors do occupy floor space and produce heat. In very cold or hot environments, additional measures (heated enclosures or extra cooling) may be required to keep ambient conditions within the recommended range (typically 5–45 °C).

By adopting an onsite nitrogen generator system, industries can eliminate the challenges of relying on external nitrogen suppliers. With advancements in PSA and membrane technologies, onsite nitrogen generation has become the preferred solution for companies looking to improve operational efficiency and reduce their carbon footprint. By selecting the appropriate PSA or membrane technology and carefully designing the system (with air filtration, controls, and buffering), industries in Europe, Southeast Asia, and the Middle East can meet their nitrogen requirements efficiently. The result is a tailored supply of N₂ — from 95% purities for general inerting to 99.999% for sensitive processes — without the recurring logistical costs and delays of traditional gas supply.