Nitrogen for Food Packaging (MAP) has become a core technology for extending shelf life while maintaining clean-label recipes and consistent product quality. By replacing most of the oxygen in the package headspace with an inert atmosphere, processors can slow microbial growth, reduce oxidation, and stabilize color and texture – without relying on heavy doses of chemical preservatives.Wikipedia +1 For engineers and scientists, the challenge is not only to understand the microbiology and gas chemistry, but also to design a nitrogen system that is safe, auditable, and correctly sized for the line.

Role of Nitrogen in Modified Atmosphere Packaging

In MAP, nitrogen is used primarily as an inert balance gas. It displaces oxygen, carries carbon dioxide into the pack, and prevents pack collapse by occupying headspace that would otherwise be filled by air. Carbon dioxide provides antimicrobial activity, while oxygen is sometimes retained at controlled levels to preserve the bright red color of red meat or to support respiration of fresh produce.wittgas.com+2

From a design perspective, three questions dominate when specifying Nitrogen for Food Packaging (MAP):

- What gas mixture is appropriate for the product?

- What nitrogen purity is required to achieve that mixture consistently?

- How much nitrogen flow and pressure are needed to support the packaging machines?

Typical MAP Gas Mixtures

Table 1 gives indicative gas compositions used in practice for common MAP products. Exact values depend on product, temperature, and shelf-life targets, but the ranges are representative.维基百科+2wittgas.com+2

Table 1 – Example modified atmospheres for selected food products

| Product category | O₂ (%) | CO₂ (%) | N₂ (%) | Notes on design focus |

|---|---|---|---|---|

| Fresh red meat | 60–80 | 20–40 | Balance (0–20) | Color stability and lipid oxidation control |

| Poultry | 0–20 | 20–40 | 40–80 | Pathogen and spoilage control |

| Cooked meats | 0–5 | 20–60 | Balance | Listeria and spoilage inhibition |

| Cheese | 0 | 30–100 | Balance | Mold growth inhibition, pack stability |

| Bakery & snacks | 0 | 0–30 | 70–100 | Oxidation and rancidity control |

| Fresh produce (salads) | 3–5 | 3–10 | 85–94 | Respiration balance, texture and color |

Nitrogen for Food Packaging (MAP) does not need to provide antimicrobial action itself; its job is to create a stable background atmosphere that supports the chosen level of carbon dioxide and any residual oxygen. Because nitrogen is poorly soluble in water and fats, it maintains pack volume even where carbon dioxide dissolves into the product.Parker Hannifin Corporation+2wittgas.com+2

Safety and Regulatory Expectations for Food-Grade Nitrogen

Food-contact nitrogen must satisfy both gas quality requirements and system-level safety controls. In most jurisdictions, nitrogen for food use is classified as a food additive or processing aid and is subject to purity and contaminant limits. Typical expectations include:fullcryogas.com+2ramdon.com+2

- High purity: Food-grade nitrogen used in MAP is commonly specified at 99.9% or higher, with residual oxygen below 1% at the point of use.fullcryogas.com+1

- Low moisture: A pressure dew point of –40 °C or lower is often required to avoid condensation, ice formation in valves, and moisture-driven microbial risks.Compressed Air Best Practices+1

- Low oil and particulate content: When nitrogen is generated on site, compressor oil carryover and particulates must be controlled with appropriate filtration and activated carbon.Compressed Air Best Practices+1

- No toxic or reactive impurities: Carbon monoxide, nitric oxides, and other reactive gases must remain below established limits; this is addressed by both gas sourcing and appropriate materials of construction.wittgas.com+1

From a food safety system point of view, Nitrogen for Food Packaging (MAP) is treated as a critical utility. Under HACCP-based programs, processors normally define at least two critical control points:modifiedatmospherepackaging.com+1

- Gas composition and residual oxygen in the pack – monitored either by in-line analyzers or by routine headspace sampling.Felix Instruments+2Onsite Gas+2

- Seal integrity and leak rate – checked by seal testers or sample-based leak detection.modifiedatmospherepackaging.com+1

Records of nitrogen purity, gas mixture set points, analyzer calibration, and packaging machine performance all form part of the food safety documentation and are typically audited alongside other process controls.modifiedatmospherepackaging.com+1

System Sizing Fundamentals

Correct sizing of a nitrogen generation and distribution system for Nitrogen for Food Packaging (MAP) starts with the packaging line and works backward to the nitrogen source. A simple, engineering-oriented approach is:

- Define the package type and headspace volume (V_headspace, in mL).

- Determine the target gas composition inside the pack and the required residual oxygen level.

- Choose a flush efficiency factor (typically 2–4 times the internal volume for form-fill-seal lines, higher for complex geometries).

- Calculate the nitrogen volume per pack.

- Multiply by packs per hour across all MAP lines to obtain the total nitrogen demand.

- Add a safety factor (10–30%) for leakage, changeovers, and future growth.eiga.eu+2Parker Hannifin Corporation+2

The following example illustrates the calculation.

Table 2 – Example nitrogen demand calculation for a snack line

| Parameter | Symbol | Value |

|---|---|---|

| Headspace volume per bag | V_headspace | 1.0 L (1,000 mL) |

| Flush factor (volumes of gas per headspace) | F_flush | 3 |

| Nitrogen fraction in flushing gas | x_N2 | 100% (pure N₂) |

| Bags per minute on MAP line | n_bag | 60 |

| Line utilization | U_line | 0.85 |

| Operating hours per day | h_op | 16 |

From these assumptions:

- Nitrogen per bag = V_headspace × F_flush × x_N2

= 1.0 L × 3 × 1.0 = 3.0 L N₂ - Nitrogen per hour = 3.0 L × 60 bag/min × 60 min/h × U_line

≈ 9,180 L/h ≈ 9.2 Nm³/h - Daily nitrogen usage ≈ 9.2 Nm³/h × 16 h ≈ 147 Nm³/day

In practice, engineers would round up and size the supply for 12–15 Nm³/h for this line to allow for higher speeds and future product SKUs. When multiple lines operate, their coincident peak demand must be considered, often using a combination of diversity factors and historical production data.

For higher-flow applications such as meat or poultry, where gas mixtures may include 20–40% CO₂, nitrogen demand is calculated in a similar way but adjusted for the nitrogen fraction in the blend. Nitrogen for Food Packaging (MAP) systems must also deliver sufficient pressure (often 3–6 bar(g)) at the MAP machine infeed to ensure fast, stable flushing and accurate gas mixing.linde-gas.com+2Parker Hannifin Corporation+2

Standard Process Flow for Nitrogen Supply to MAP Lines

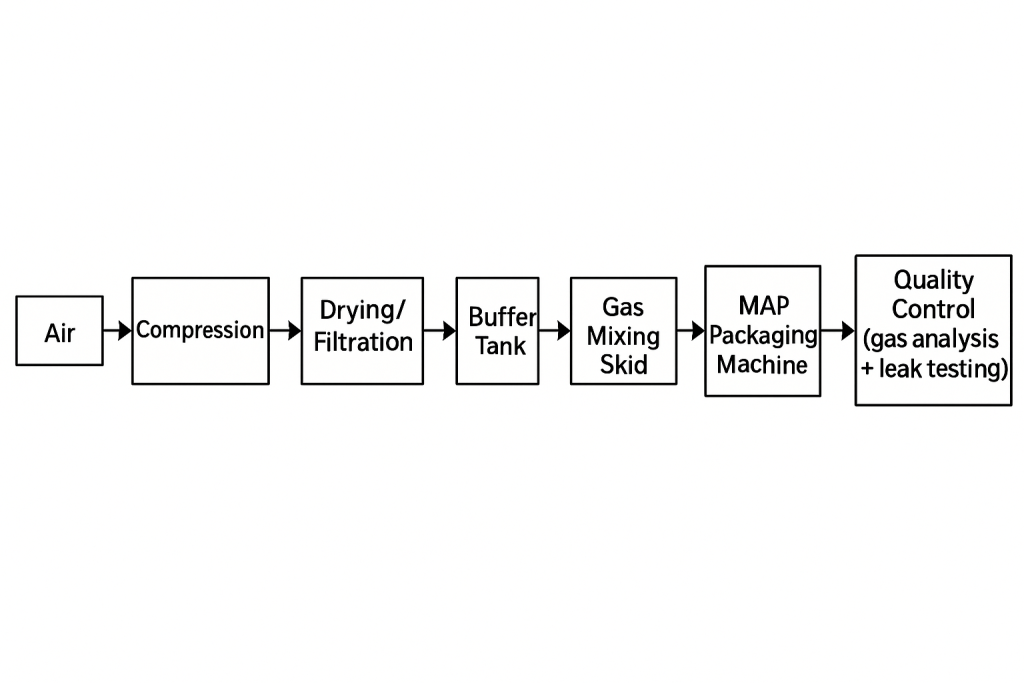

Although each plant is unique, a fairly standard process flow can be defined for Nitrogen for Food Packaging (MAP). The diagram below describes a typical on-site generation arrangement:eiga.eu+2OXYMAT+2

- Ambient air intake

- Air compressor

- Primary filtration and dryer (refrigeration or desiccant)

- Fine filtration and oil removal

- Nitrogen generator (PSA or membrane)

- Nitrogen buffer vessel

- Distribution header and pressure regulation

- Gas mixer (N₂/CO₂/O₂) and flow control to each MAP machine

- In-line gas analyzer and pack seal check

- Headspace verification and record keeping

Represented as a simplified flow diagram:

Air → Compression → Drying/Filtration → N₂ Generator → Buffer Tank → Distribution Manifold → Gas Mixing Skid → MAP Packaging Machine → Quality Control (gas analysis + leak testing)

Where nitrogen is supplied from bulk liquid storage instead of on-site generation, the upstream blocks are replaced by a storage tank, vaporizer, and pressure control station, but the downstream MAP process remains similar. Well-designed Nitrogen for Food Packaging (MAP) installations also include clearly labelled isolation valves and bypass lines so that parts of the system can be serviced without stopping production.Compressed Air Best Practices+1

Design and Operational Best Practices

To keep Nitrogen for Food Packaging (MAP) systems robust over the long term, several design and operational practices are recommended:

- Align gas mixture with product science: Meat, cheese, baked goods, and fresh produce all respond differently to oxygen and carbon dioxide. Shelf-life studies and challenge tests should be used to validate the chosen gas recipes.Felix Instruments+2pmc.ncbi.nlm.nih.gov+2

- Protect compressed air quality: Poor air quality degrades nitrogen generator performance and can introduce off-flavors or contaminants. Monitoring dew point, oil, and particulates upstream of the generator is essential.Compressed Air Best Practices+1

- Use adequate buffer volume: A well-sized buffer vessel helps decouple generator dynamics from fast packaging machine transients, avoiding pressure dips and composition swings.eiga.eu+1

- Instrument the system: Pressure transmitters, flow meters, and inline gas analyzers provide the data needed for troubleshooting, continuous improvement, and audit trails.Felix Instruments+1

- Plan for maintenance and redundancy: Dual generators, spare compressors, and bypass connections for cylinder backup can prevent downtime during maintenance or unexpected failures.OXYMAT+1

- Integrate with food safety programs: Nitrogen purity, gas mixture set points, analyzer calibrations, and leak-test records should be embedded into HACCP or equivalent food safety plans.modifiedatmospherepackaging.com+2fda.gov+2

Summary

For engineers and technical staff, designing Nitrogen for Food Packaging (MAP) is a multidisciplinary task that brings together gas chemistry, microbiology, process engineering, and food safety. Nitrogen itself is chemically simple, but the system that delivers it – from compressed air quality and generator selection through to gas mixing, pack flushing, and headspace verification – determines whether a MAP program truly extends shelf life and protects brand quality.Onsite Gas+2Wikipedia +2 By grounding design decisions in product-specific gas mixtures, rigorous safety standards, and realistic system sizing, it is possible to build nitrogen infrastructure that is efficient, auditable, and ready to support future growth in MAP applications.