principle

The oxygen generator device is carefully developed using the principle of PSA pressure swing adsorption, using a high-quality oxygen making molecular sieve as the adsorbent to directly separate oxygen from the air at room temperature. Compressed air subjected to dry purification treatment. Entering the adsorption tower equipped with molecular sieves, nitrogen, carbon dioxide, moisture, etc. in the air are largely adsorbed into the molecular sieve solid phase, while oxygen is enriched in the gas phase due to the small adsorption amount.

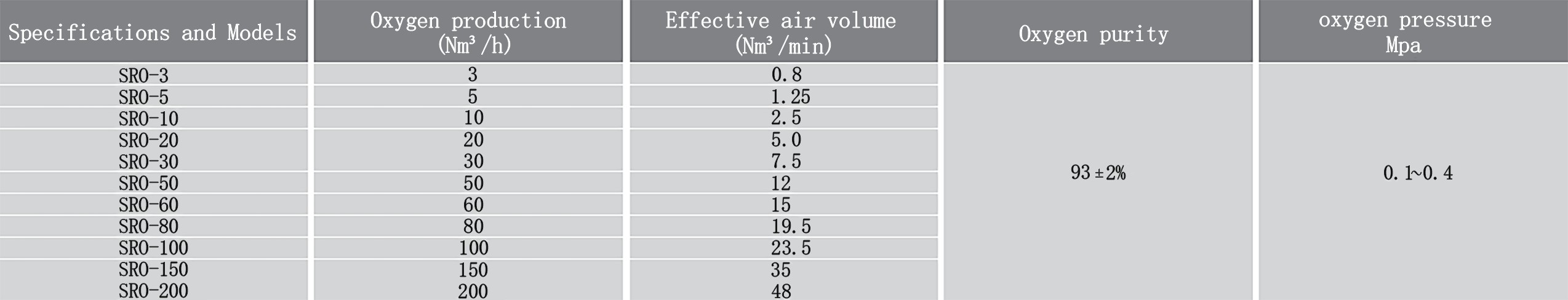

Technical Parameters

氧氣產量:3~ 200Nm/h 氧氣純度:93 + 2 % (標準型為93 % )

氧氣壓力:0.1~ 0.4Mpa (可調) 氧氣常壓露點: -43 ° C

Features

- 整機運行可靠:先進嘅製氧工藝流程設計、科學嘅氣體分佈結構、獨有嘅分子篩填裝工藝、特有制氧分子篩保護措施同氣缸自動壓緊補償裝置幾者嘅有機結合,有利於製氫分子篩嘅長期使用。連續生產穩定採用進口 PLC 控制系統同切換壽命達300萬次嘅進口氣動閥門,高效可靠:確保裝置嘅連續可靠運行。

先進嘅控制系統: PLC 控制系統,自動化程度高,可選擇觸控屏控制系統,採用人性化界面設計,具有多畫面顯示功能,可喺線顯示氨氣純度、流量、壓力、故障信號等參數,並可喺線修改運行參數,帶有遠程監控、遠傳信號同遠程開停機功能,自動化程度高,操作簡單,可實現全自動無人操作,並可同用戶 DCS 系統聯控。

運行成本低:同其他(包括深冷法製氧、液氧、鋼瓶氧)相比,喺中小規模裝置中, PSA 製氧嘅運行成本更低。

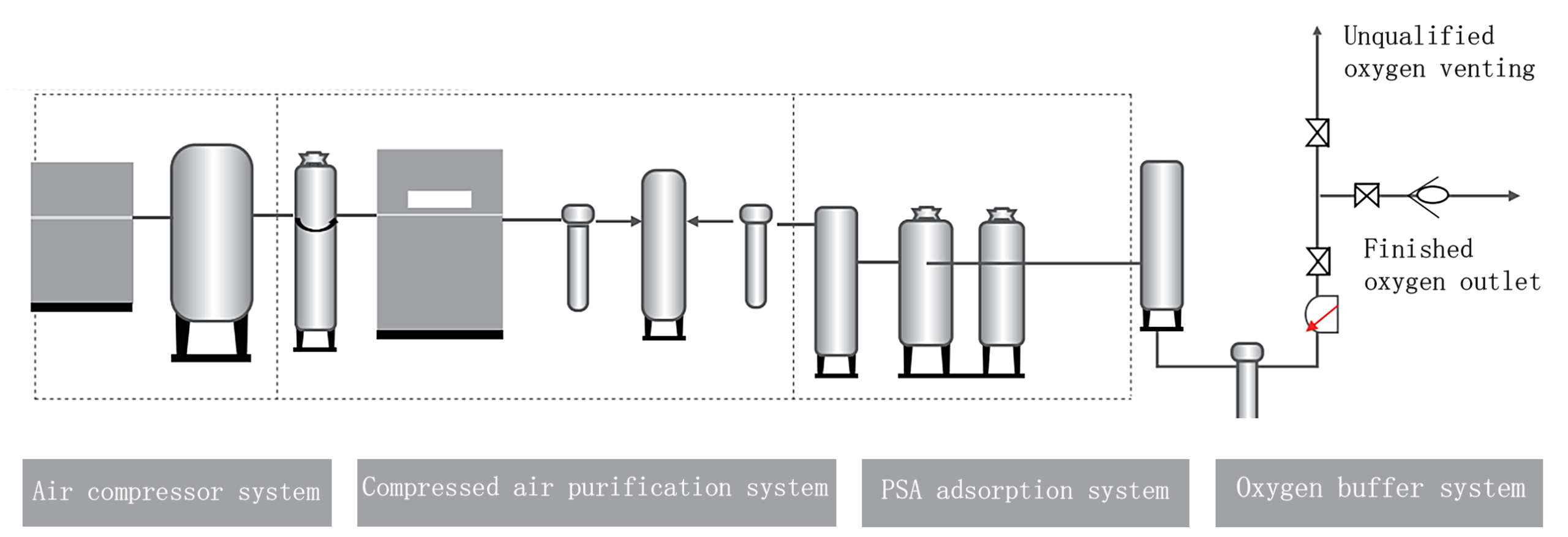

Process

Air compressor system

The oxygen concentrator air compressor system mainly includes an air compressor and an air buffer tank. The air is compressed to the set pressure value through the air compressor and the air pressure is stabilized by the buffer tank.

Compressed air purification system

The compressed air purification system compression of the oxygen concentrator includes a funny degreaser, a refrigerated dryer, an activated carbon filter, and a precision filter. The air is first removed from part of the oil, water, dust by the gas-water separator, pipe filter, then further removed by the combined dryer, the fine filter removes oil, dust, and is deeply purified by a precision filter that follows.

PSA adsorption system

It mainly consists of an oxygen filtration system, an oxygen buffer tank, a CNC system, an oxygen analyzer, and a flow meter. Oxygen taken from the PSA oxygen production mechanism will first be stored in an oxygen buffer tank. Oxygen Buffer Tank Function: Balances the pressure and oxygen content of the product gas and provides a regenerative gas source for the process tank of the oxygen-nitrogen separation device.

Oxygen buffer system

The core part of the oxygen generator is the PSA adsorption system, which consists of an air process storage tank, adsorption tower, pneumatic valve, PLC controller, and compression device. The compressed and purified gas passes through the oxygen-generating molecular sieve of the adsorption tower to separate the produced oxygen. The dual-tower structure One tower adsorption oxygen production, one tower desorption regeneration, combined with PLC controlled cycle alternating two towers, produces high quality oxygen.

Oxygen concentrator specifications