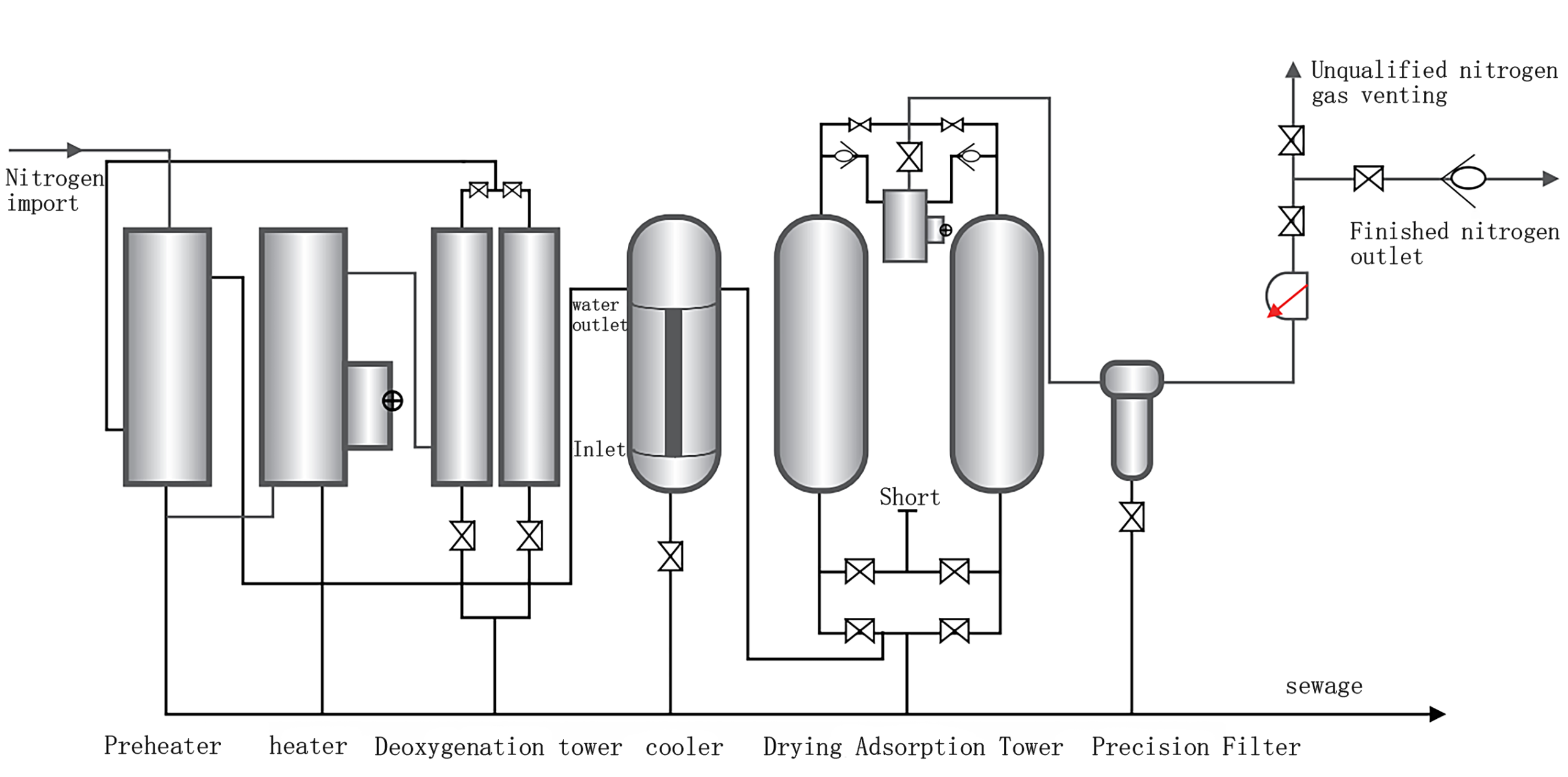

How it works

The carbon-added purification device oxidizes residual oxygen to CO2 (C+O2→CO2) with a carbon catalyst at an appropriate temperature, then removes CO2 and moisture through PSA pressure adsorption depth, and cooperates with fine filtration to remove particulate impurities. Raw nitrogen is fed, the catalyst is consumable and regularly replenished, no hydrogen source is required, the overall operating cost is more ideal, suitable for semiconductor, electronics, laser processing and metal heat treatment and other extremely sensitive to residual oxygen working conditions.

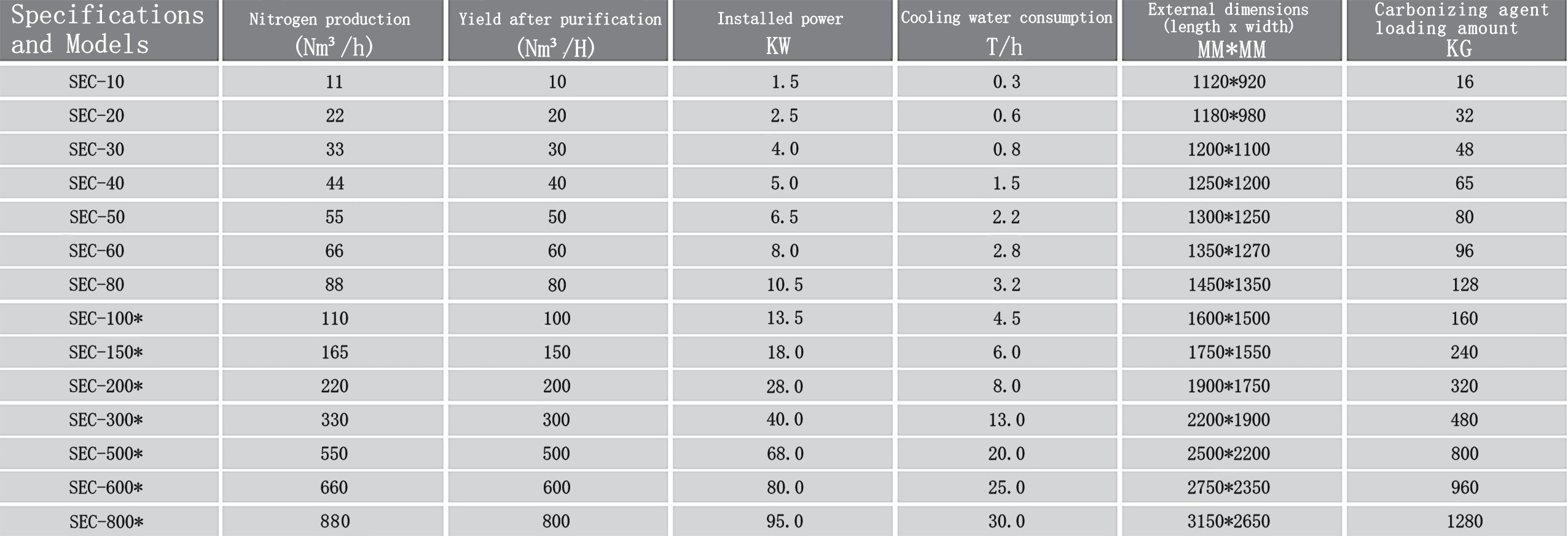

Technical Parameters

Nitrogen output: 10~ 800Nm/h Nitrogen purity: ≥ 99.9995%

Carbon dioxide content: ≤ 5PPm Pressure drop: 0.1Mpa

Oxygen content: ≤ 5PPm Nitrogen atmospheric pressure dew point: -60°C

Features

High-efficiency carbon catalytic deoxidation: At an appropriate temperature, the residual oxygen is oxidized into CO₂. The process is mature and stable, producing high-purity nitrogen (up to 5N grade), and the final nitrogen product contains no hydrogen, making it suitable for applications requiring strict control of hydrogen and oxygen content.

High-temperature-resistant structure: The deoxidizer and heater are made of high-temperature-resistant materials, with dual heaters (one in use and one standby) for stable temperature and high reliability.

Energy-saving preheating recovery: The newly added preheater recovers the sensible heat from the nitrogen after deoxidation, resulting in an overall energy consumption reduction of ≥30%.

Deep purification link: The PSA/adsorption dryer performs deep CO₂ removal and dehydration, featuring large adsorption capacity, long cycle time, and low energy consumption; at the end stage, a fine filter removes particulate impurities.

Maintenance without shutdown: With dual deoxidation towers (one in use and one standby), carbon catalyst can be replenished directly during continuous operation; when the catalyst is exhausted, no impurity powder residue remains and no purging is required.

Control and Safety: Controlled by a Siemens PLC from Germany, equipped with automatic interlock venting and multiple fault alarms for safer operation and improved visualization.

Process

Technical Specifications