Equipment Introduction

The micro-heat regenerative dryer, fully known as the micro-heat regenerative adsorption dryer, is a type of equipment that dries compressed air based on the principle of pressure swing adsorption with heated regeneration. It is developed by combining the advantages of both heated and heatless regenerative dryers, resulting in an energy-saving and highly efficient drying system. In this design, the regeneration gas is slightly heated by a micro-heater before being used to purge and regenerate the adsorbent inside the adsorption tower, effectively reducing regeneration air consumption, achieving excellent regeneration performance, and allowing for a longer adsorption working cycle.

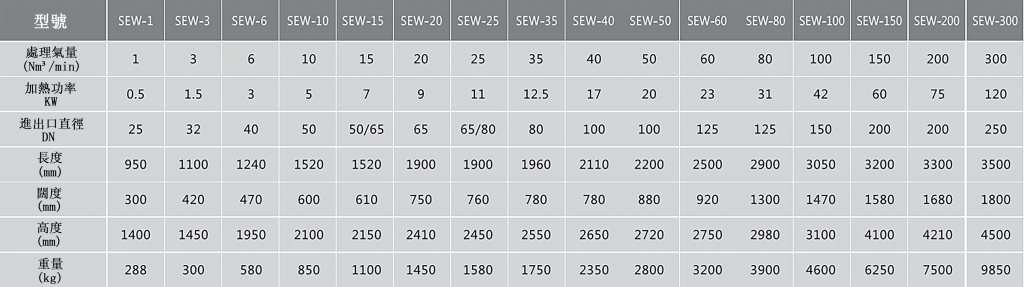

Technical Parameters

Working Pressure: 0.6–1.0 MPa (1.0–3.0 MPa available upon request) Inlet Air Temperature: ≤ 45°C Outlet Air Dew Point (at atmospheric pressure): –40°C (Activated Alumina), –60°C (Molecular Sieve) Regeneration Air Consumption: ≤ 4–6% Pressure Drop: ≤ 0.023 MPa

Working principle of micro-heat regeneration dryer

The working principle of the microthermal regeneration dryer is that one adsorption tower performs adsorption drying under working pressure, and the corresponding other adsorption tower draws a very small amount of compressed air from the main pipeline through the decompression, heating process, and performs microthermal regeneration as a regeneration gas. Microthermal regenerated desiccant. There is a larger reduction in its residual water content, which improves the treatment capacity of the device. First. A small amount of the finished gas is taken from the outlet as the regeneration required for regeneration, the regeneration is heated through a microheater (heated to about 150 °C), and then the regas enters the regeneration tower to resolve the required adsorbent and remove the moisture in the adsorbent to achieve the adsorbent regeneration effect. Minimize energy consumption. This series of product sets has the advantages of thermal regeneration and no thermal regeneration, and adopts micro-heating for the regeneration form, thereby reducing the regeneration gas consumption and achieving the purpose of energy saving.

Micro-heat dryer product features

- Equipped with an automatic pressurization and pressure equalization process to reduce the impact of airflow on the adsorbent.

Flanged filling and discharge ports make desiccant replacement easy and convenient.

A scientifically optimized flow rate design and the use of high-quality adsorbents ensure a stable dew point of the outlet air.

The specially designed gas distributor guarantees uniform airflow distribution, allowing full contact between compressed air and the adsorbent, preventing adsorption “dead zones” and “tunnel effects.”

Adopts a PLC program controller with LCD display and touch keys, allowing adjustment of working and regeneration times according to actual operating conditions.

Drying and regeneration status display with automatic temperature control helps save energy. The control air source is taken from the outlet of the adsorption tower (dry air) to prevent oil and moisture contamination of valves and air circuits, avoiding valve corrosion and blockage.

High-quality heating and control components ensure long-term reliable operation, while premium pneumatic valves feature fast switching, high efficiency, and durability.

Micro-heat regeneration dryer parameters