Equipment Introduction

The blower purge adsorption dryer is a type of compressed air drying equipment that utilizes normal-temperature adsorption and external blower heated regeneration technology. The system uses a blower to deliver hot air, which removes the moisture from the desiccant to achieve regeneration.

Its main feature is that no compressed air is consumed during the heating regeneration stage; only a small amount of air is required during the cooling purge phase. Therefore, the overall regeneration air consumption is much lower than that of micro-heat dryers, resulting in higher energy efficiency.

This energy-saving dryer is especially suitable for low-pressure air systems or industrial applications with strict energy consumption requirements, such as electronics manufacturing, food packaging, and medical gas treatment.

Technical Parameters

Working Pressure: 0.5–1.0 MPa Inlet Air Temperature: ≤ 40°C Inlet Air Oil Content: < 0.1 mg/m³ Regeneration Air Consumption: ≤ 3% Pressure Drop: ≤ 0.023 MPa Atmospheric Dew Point: ≤ –40°C

Basic features of blast regeneration adsorption dryer

- Low regeneration air consumption: The system uses an external blower for hot air regeneration, eliminating the need for a large amount of compressed air. Compared with micro-heat dryers, it is more energy-efficient and has lower operating costs.

- High-efficiency and low-noise tri-lobe Roots blower: Equipped with a high-performance tri-lobe Roots blower, featuring stable airflow, low vibration, and low noise, ensuring the stable and reliable operation of the entire compressed air drying system.

- Mature structural design and easy maintenance: The overall design is similar to that of the micro-heat regenerative adsorption dryer, featuring simple control, convenient operation, and low maintenance cost.

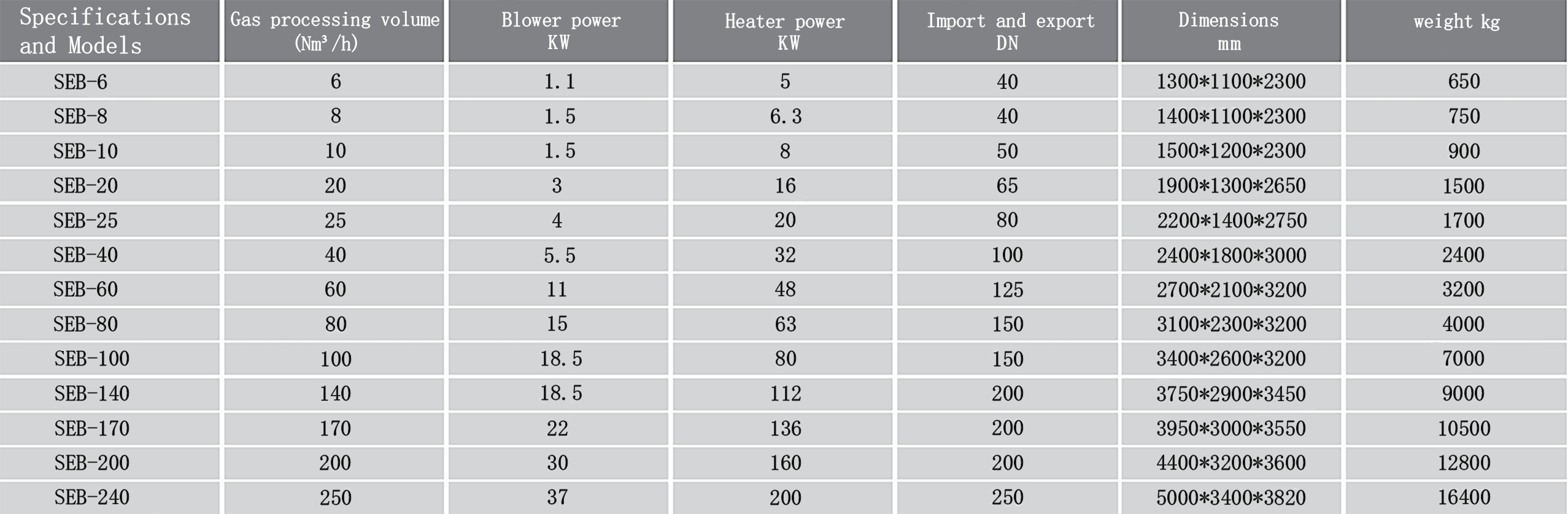

Specifications of Blast Regeneration Adsorption Dryer