Equipment Purpose

The dehydration column utilizes a molecular sieve to adsorb moisture in the ppm fraction of the solvent so that the solvent moisture content reaches the production use requirements.

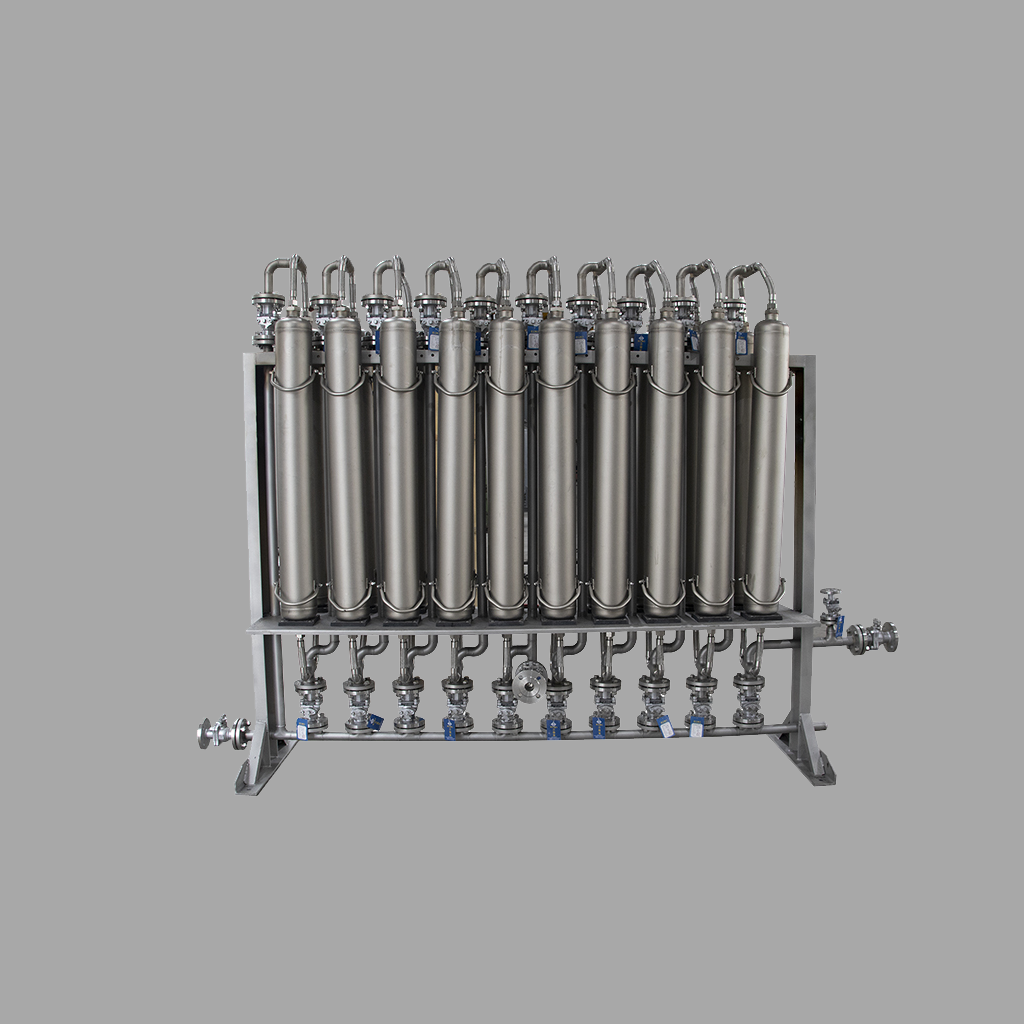

Device structure

- Equipped with a base support and quick fastening devices for the fixed molecular sieve column.

The molecular sieve column adopts a hanging installation method.

The solvent flow pipelines must be securely fixed.

A grounding device is provided for convenient equipment grounding.

304 flexible corrugated hoses with special connectors are used to connect to the molecular sieve column ports.

Dehydration Column Introduction

A dehydration column is a filtration device used to remove contaminants from liquids. It usually consists of an enclosure and one or more filter cartridges whose purpose is to capture particulates and impurities as the liquid passes through the unit. The dehydration column belongs to a type of cartridge filter, which is commonly used in various applications, including water treatment agents, chemical processing, food and beverage production and pharmaceuticals. They can be made from a variety of materials, including plastic, stainless steel, and other metals, depending on the specific application and requirements.

The filter itself can also be made from a range of materials, including paper, polymerase, and nylon. The choice of filter material will depend on the size and type of particles that need to be removed from the liquid. One of the advantages of cartridge filter units is that they are relatively easy to install and maintain. The filter cartridge can be easily replaced when clogged or dirty, the shell can be cleaned and reused several times. Cartridge filter units are a reliable and cost-effective way to remove impurities from liquids in a wide range of applications.