Introduction to Cryogenic Air Separation

Cryogenic Air Separation Technology is currently the most mature and stable method of industrial gas production, widely applied in the fields of chemical, energy, metallurgy, electronics, new materials, and pharmaceuticals. In the Hong Kong and international markets, cryogenic air separation equipment can steadily provide high-purity nitrogen, oxygen, and rare gases, offering a reliable gas source for precision processes across various industries. The PSA (Pressure Swing Adsorption) nitrogen generator uses carbon molecular sieve as the adsorbent and produces nitrogen based on the principle of pressure swing adsorption. Under certain pressure conditions, oxygen and nitrogen in the air exhibit different adsorption capacities on the surface of the carbon molecular sieve — that is, the carbon molecular sieve adsorbs oxygen much more strongly than nitrogen. Through the programmable control of pneumatic valve switching, the A and B towers operate alternately, allowing the nitrogen generator to complete the pressurization adsorption and depressurization desorption cycles, ultimately separating oxygen and nitrogen to obtain nitrogen gas of the desired purity.

Cryogenic air separation process

- The raw air is first compressed by the air compressor to a pressure of 0.7–0.85 MPa, and then enters the precooling system where it is cooled down to 5–10 °C to remove most of the moisture.

Subsequently, the air flows into the cryogenic purifier (molecular sieve adsorption system), which further adsorbs and filters out the remaining moisture, carbon dioxide, and hydrocarbons to ensure that the feed air entering the distillation column is clean and impurity-free. - After purification, the air enters the expander for expansion refrigeration, generating the required low-temperature cooling capacity to provide conditions for subsequent liquefaction and separation.

In the main heat exchanger, the compressed air exchanges heat with the returning nitrogen, oxygen, and waste nitrogen streams — cooling the air to near its liquefaction temperature while simultaneously warming the return gases to near ambient temperature. - The nitrogen is further subcooled in the subcooler, allowing the liquid air and liquid nitrogen to reach thermal equilibrium before throttling. Subsequently, the air enters the high- and low-pressure distillation column system for separation.

High-purity nitrogen product is withdrawn from the top of the upper column.

Obtain high-purity oxygen product at the bottom of the upper tower.

- The entire cryogenic air separation process has a compact structure and high energy efficiency, and can stably provideHigh-purity nitrogen and oxygen, widely used in chemical, electronics, new energy, steel, medicine and other industries.

Powertrain

The power system in the cryogenic air separation unit consists mainly of a raw air compressor. Air separation equipment obtains oxygen, nitrogen and other gases through a low-temperature separation process, which is essentially the process of energy conversion. The energy of the entire device is mainly input from the compressor, and most of the total energy consumption required for air separation is consumed by the raw air compressor. Therefore, the performance of the compressor directly determines the energy efficiency level of the air separation system.

purification system

The purification system consists of an air precooling system (air cooling system) and a molecular sieve purification system. The compressed air is cooled by contact heat exchange through a precooler and acidic impurities removed;

Refrigeration system

The deep cooling air separation equipment relies on expansion refrigeration operation, and the whole system strictly follows the classic refrigeration cycle principle. When the refrigeration system of the air separation device is mentioned, it mainly refers to the expander, which generates cold through the adiabatic expansion of high-pressure air, provides a low temperature environment for the cold box, so that the air liquefies and completes gas separation, is the core refrigeration unit of the entire air separation system.

Heat exchange system

The heat balancing of the deep-cooled air separation equipment is jointly accomplished by the refrigeration system and the heat exchange system. The heat exchanger is responsible for cold recovery and temperature regulation to ensure that the airflow reaches a stable thermal balance. Modern air separation devices mostly adopt aluminum plate-fin heat exchangers, which have the advantages of fast heat conduction, high efficiency, and compact structure, making the entire system more stable and energy-saving.

Distillation system

The core of deep-cooled air separation equipment, important equipment to achieve low-temperature separation. Two-stage distillation at high and low pressure is usually adopted. It mainly consists of a low-pressure tower, a medium-pressure tower, and a condensing evaporator.

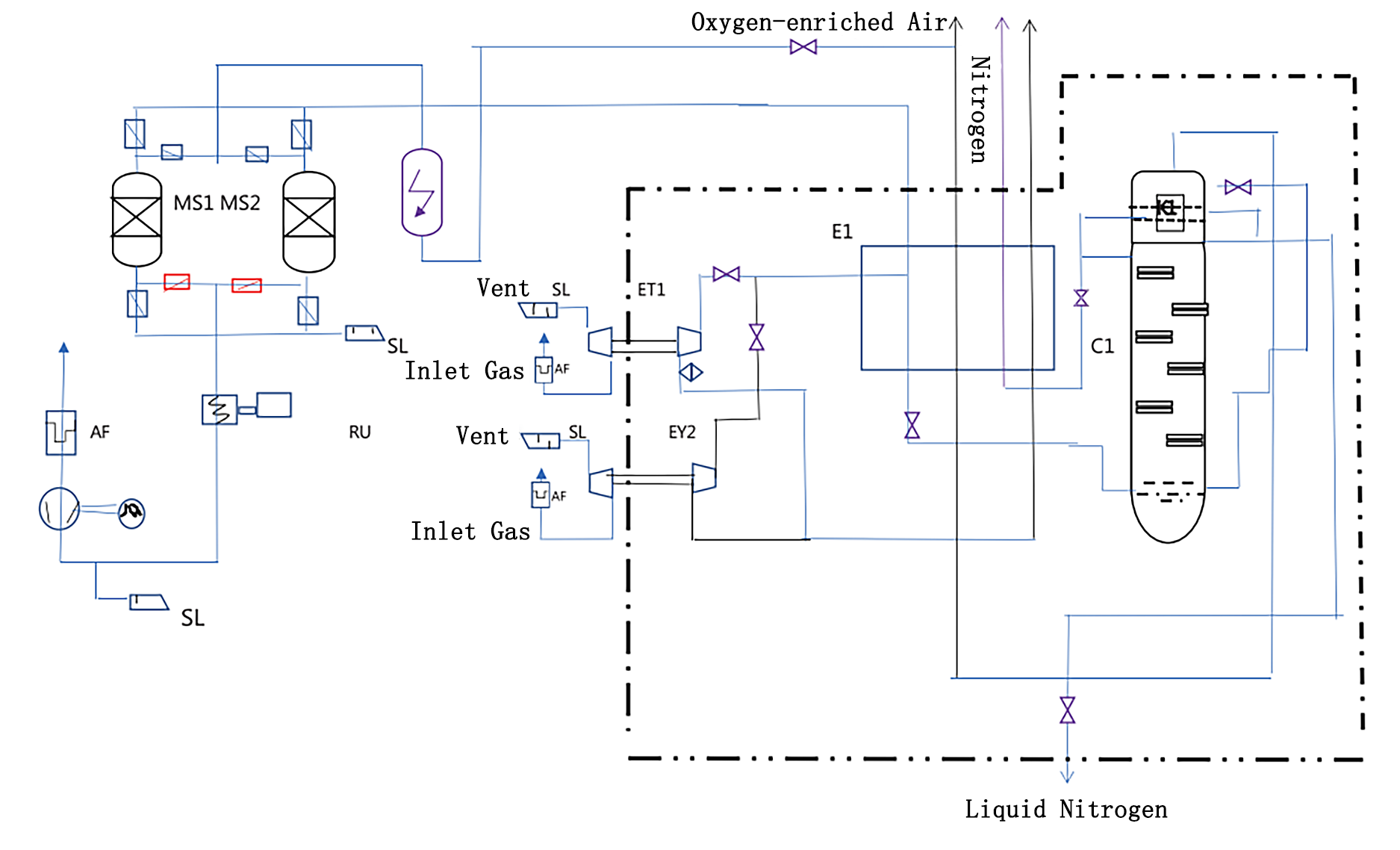

Cryogenic air separation forward flow expansion nitrogen production

- It is generally suitable for situations where the user has lower pressure requirements for nitrogen products (e.g., less than 0.2 MPa).

- After the raw air undergoes dust removal, compression, precooling, and purification, it is divided into two streams:

The first stream of air enters the main heat exchanger, where it exchanges heat with the returning waste nitrogen. After being cooled to a certain temperature, it is extracted from the middle section of the heat exchanger for expansion. The expanded low-temperature air then enters the bottom of the nitrogen column to participate in rectification.

Thesecond air is cooled to saturation temperature in the main heat exchanger and enters the nitrogen tower directly through the throttle valve to complete the gas-liquid separation with the former.

- At the top of the nitrogen column, product nitrogen is obtained.

The oxygen-enriched liquid air from the bottom of the nitrogen column is throttled and then enters the evaporation side of the condenser–evaporator, where it is used to condense the gaseous nitrogen from the top of the column.

The oxygen-enriched gas drawn from the top of the condenser–evaporator is returned to the cold end of the main heat exchanger, where it exchanges heat with the forward-flowing air and is reheated to ambient temperature before leaving the cold box.

A portion of this gas is used for molecular sieve adsorber regeneration, while the remainder is vented directly. - Eventually, the nitrogen obtained from the top of the nitrogen tower is discharged to the cold box after being reheated to normal temperature by the main heat exchanger and supplied to the client for use.

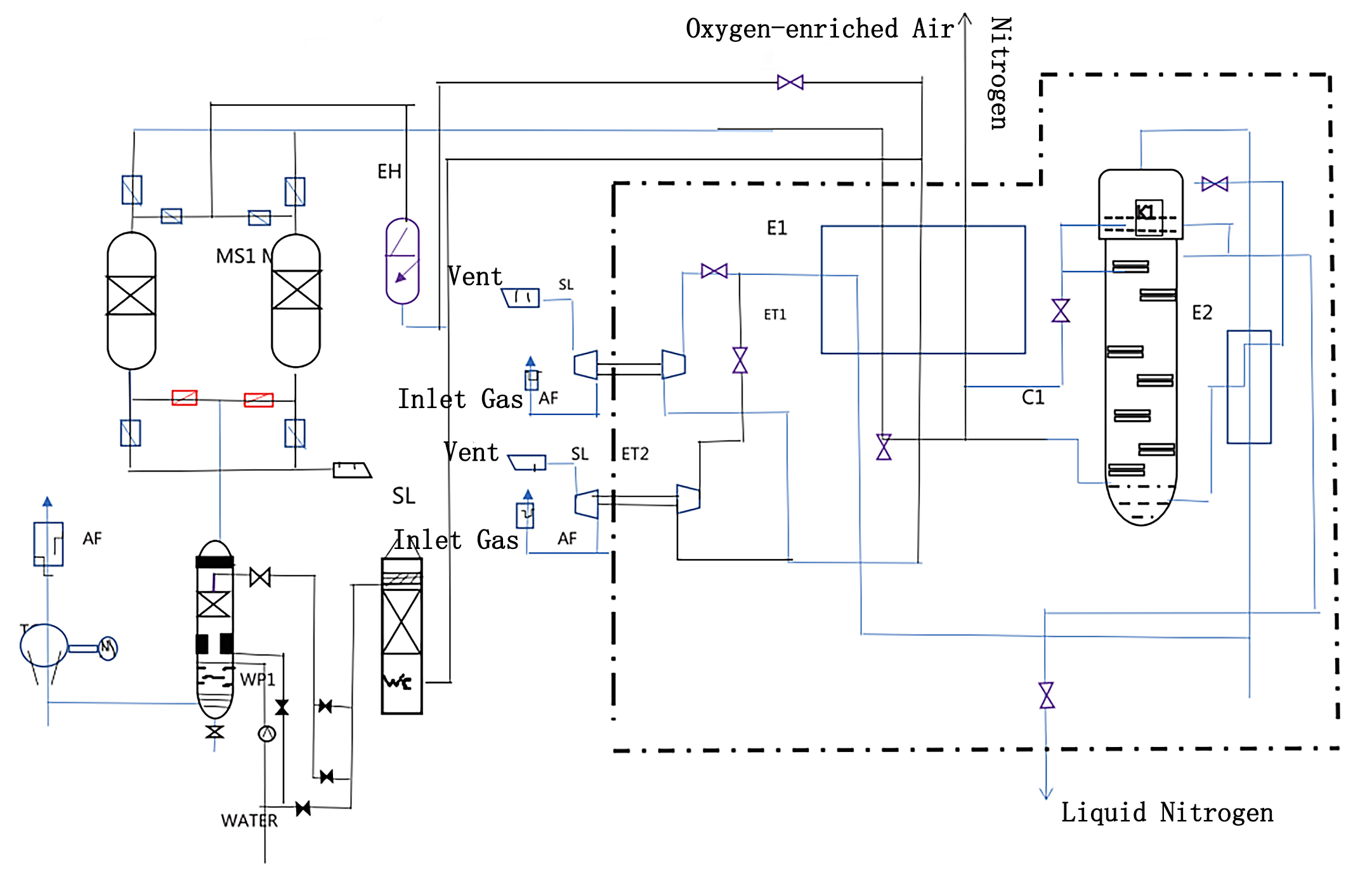

Countercurrent expansion nitrogen generation

- It is generally suitable for occasions where the user has certain requirements for the pressure of nitrogen products (such as higher than 0.2 MPa).

- After the raw air undergoes dust removal, compression, precooling, and purification, it enters the main heat exchanger.

In the main heat exchanger, it exchanges heat with the returning waste nitrogen. The air is cooled to its saturation temperature and carries a small amount of moisture before

entering the bottom of the nitrogen column for rectification and separation. - At the top of the nitrogen column, product liquid nitrogen and gaseous nitrogen are obtained.

The oxygen-enriched liquid air from the bottom of the nitrogen column is throttled and enters the evaporation side of the condenser–evaporator,

where it is used to condense the gaseous nitrogen from the top of the column, completing the gas–liquid heat exchange process. - Most of the oxygen-enriched gas drawn from the top of the condenser–evaporator returns to the cold end of the main heat exchanger.

After being reheated to a certain temperature, it is extracted from the middle section and enters the turboexpander for expansion,

providing the necessary refrigeration for the entire pure nitrogen system. - The expanded oxygen-enriched air mixes with another throttled oxygen-enriched stream,

and together they re-enter the cold end of the main heat exchanger to exchange heat with the forward-flowing air.

Finally, the gases are reheated to ambient temperature and discharged from the cold box.

A portion of the gas is used for molecular sieve adsorber regeneration, while the remainder is vented. - The nitrogen from the top of the nitrogen tower is reheated to normal temperature by the main heat exchanger and then discharged from the cold box and supplied to the user.

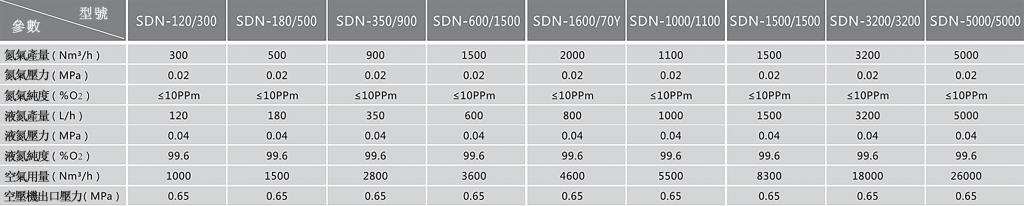

Specifications of cryogenic air separation equipment