Equipment Introduction

The refrigerated air dryer utilizes the principle of refrigeration dehumidification to condense and separate the moisture contained in compressed air, thereby achieving a drying effect.

The entire machine adopts high-quality imported refrigeration components, ensuring stable operation, low noise, low energy consumption, and easy maintenance.

Because it requires no foundation installation and has a compact structure, it offers flexible installation and convenient operation, making it widely used in industrial compressed air drying systems.

Sheng Er Gas (Hong Kong) provides various models of refrigerated dryers and adsorption dryers as well as industrial gas purification equipment, which are widely applied in industries such as electronics manufacturing, food packaging, pharmaceuticals, and machinery processing.

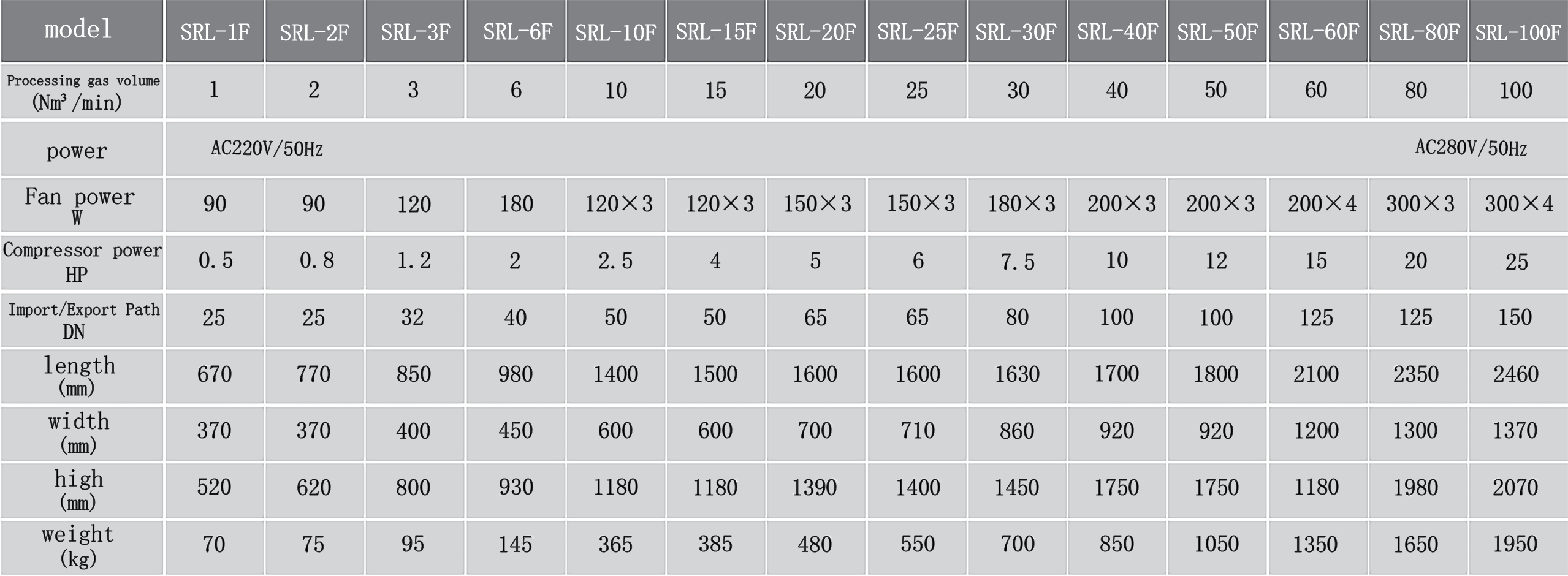

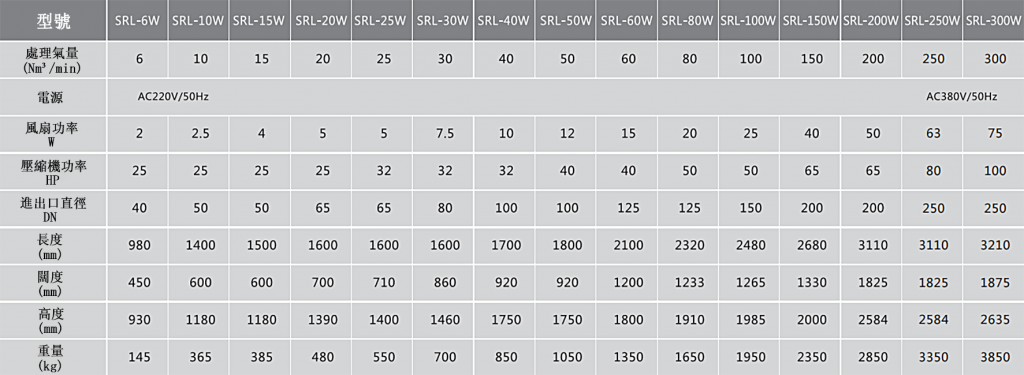

Technical Parameters

Working Pressure: 0.6–1.0 MPa (1.0–4.5 MPa available upon request) Inlet Air Temperature: < 45°C

Outlet Air Pressure Dew Point: 2–10°C Pressure Drop: < 0.025 MPa

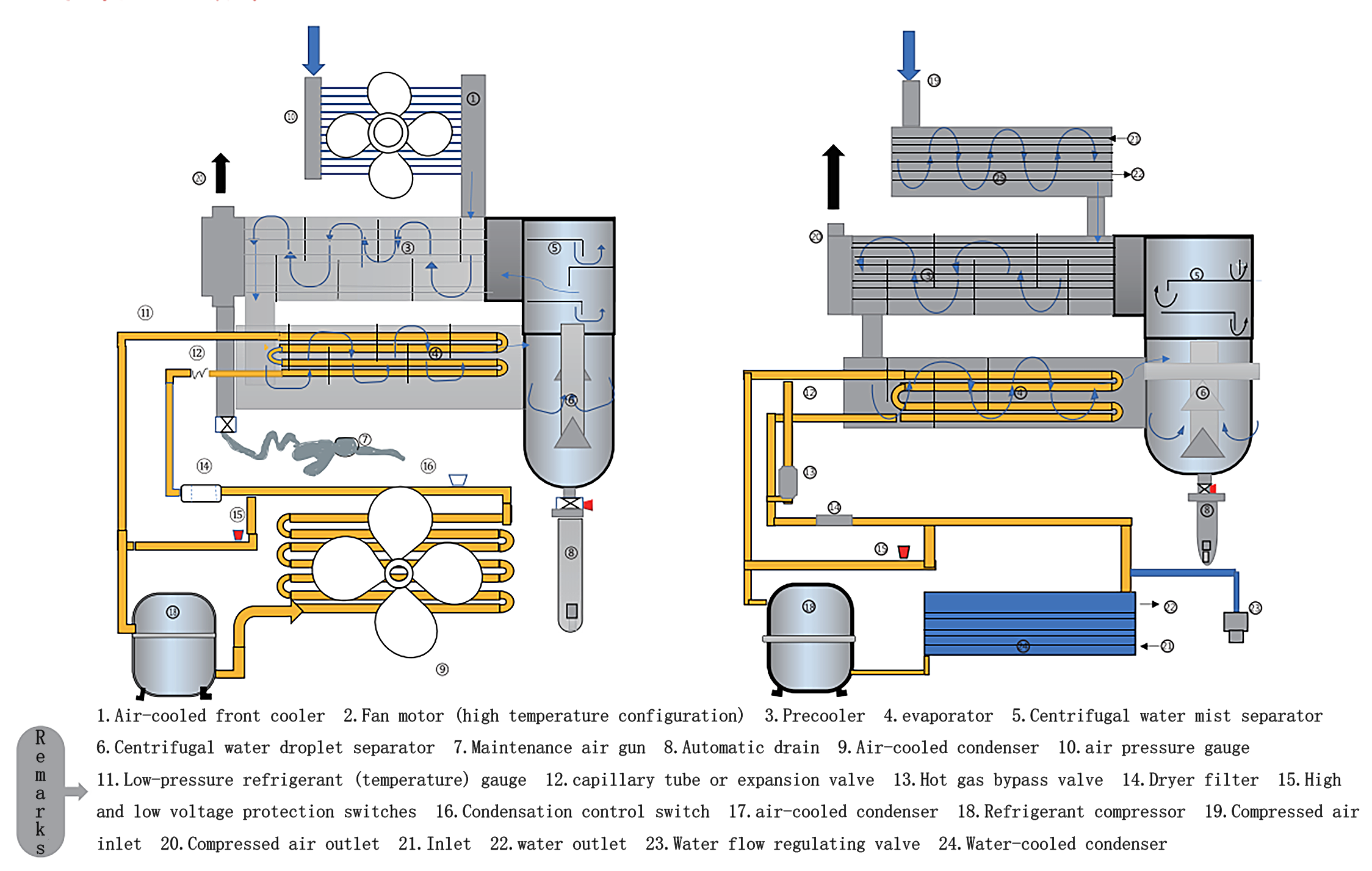

Process flow chart

Gas system

The compressed air is cooled to 2°C~10°C by the high-efficiency precooler 3 and the evaporator 4, enters the gas-water separator 6 to remove the condensed moisture, and finally returns to the high-efficiency precooler for reheating.

Refrigerant system

The cryogenic drying mechanism After being supercharged within the refrigeration compressor 18 , the refrigerant is cooled by a condenser 9 or 24 , gassed after being converted to a cryogenic liquid by 12 and enters the evaporator 4 to absorb heat from the compressed air, and is cyclically compressed by the refrigeration compressor after passing through the gas-liquid separator.

Features

Long-term reliability

The refrigerated air dryer adopts a scientific airflow design, ensuring stable dehumidification performance and minimal air pressure drop.

All refrigeration compressors and components are selected from internationally renowned brands and equipped with high- and low-pressure protection devices to ensure long-term stable operation of the equipment.

Highly efficient energy-saving design

Equipped with a hot gas bypass valve, which automatically adjusts according to the load to prevent compressor icing and maintain a stable dew point.

Uses an electronic drain or automatic drainage system to effectively discharge condensate water.

Designed with high-quality threaded copper tubes, providing a large heat exchange area and high efficiency.

The precooler recovers cooling energy, resulting in low overall power consumption and excellent energy-saving performance.

All refrigeration systems and evaporator surfaces are designed with insulation layers to reduce cooling losses.

Stable dew point control

Equipped with a dual automatic balance control system (hot gas bypass valve + thermostatic expansion valve), ensuring a stable dew point even under varying load conditions.

The high-precision temperature control system ensures a stable and reliable dew point of the outlet air.

Smart Control System

The whole machine adopts a Siemens PLC controller from Germany, and the LCD screen can display in real time the condensing temperature, evaporating temperature, inlet and outlet air temperatures, and dew point temperature.

Equipped with automatic control, fault alarm, temperature monitoring, and remote linkage functions.

It can realize linkage control with the air compressor, and is easy to operate and maintain.

Simple Maintenance

The electronic / automatic drain features a timed cleaning design to prevent clogging.

The air-cooled unit can be periodically cleaned with an air gun to blow off the condenser, maintaining excellent heat dissipation performance.

Technical Specifications