principle

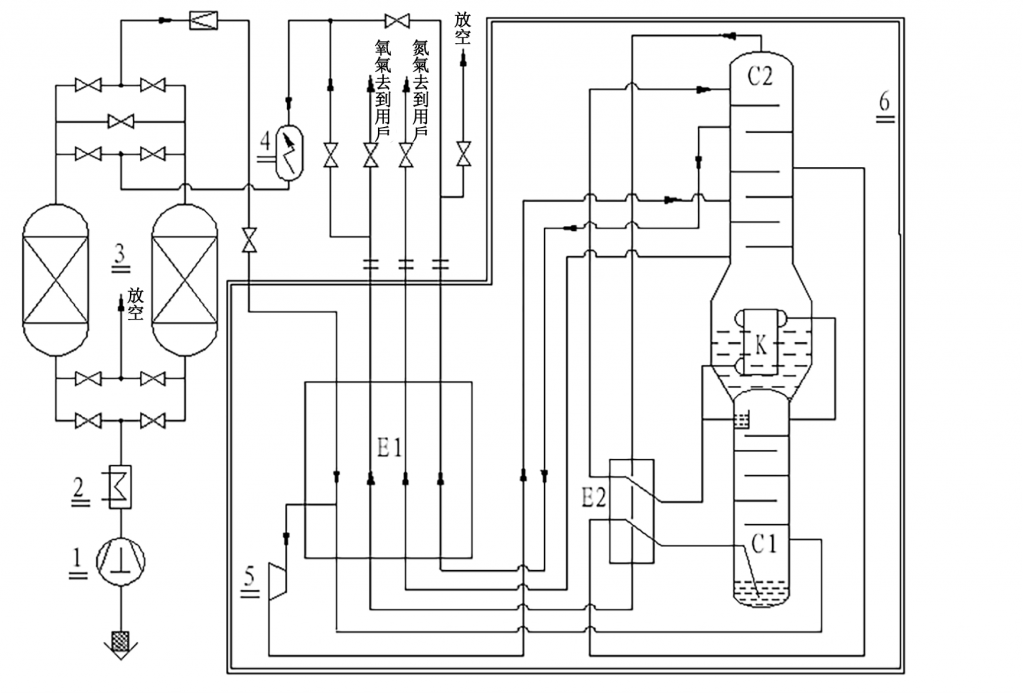

Cryogenic air separation nitrogen production is a traditional nitrogen production method with a history of several decades. Cryogenic nitrogen production equipment uses air as raw material, compresses and purifies it, and then uses heat exchange to liquefy the air into liquid air. Liquid air is mainly a mixture of liquid oxygen and liquid nitrogen. The different boiling points of liquid oxygen and liquid nitrogen are used to separate them to obtain nitrogen through the distillation of liquid air.

Cryogenic Nitrogen Generation Equipment EPC General Contracting Project | Process Flow

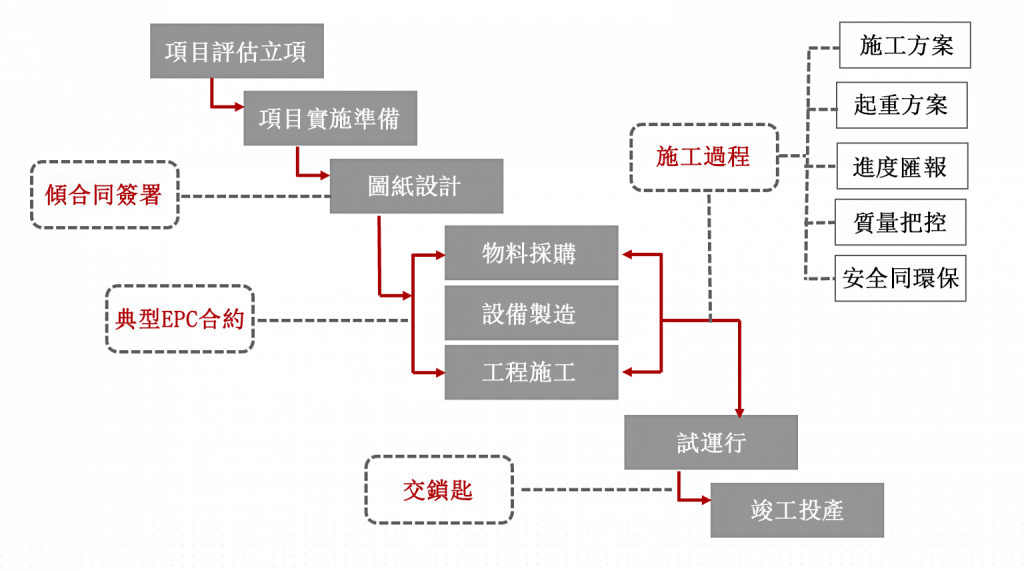

- Cryogenic air separation EPC general contracting refers to the full-process general contracting of the cryogenic air separation project by the engineering company for design (Engineering), procurement (Procurement), and construction (Construction). It is fully responsible for the safety, quality, progress, and cost of the project, and ultimately delivers a complete air separation unit that meets the contract requirements and is ready for production and operation. As the EPC general contractor, Zhejiang Shenger is responsible for the design, procurement, construction, installation, and later operation and maintenance of the entire cryogenic air separation project, and delivers the final air separation unit that is ready for use to the owner.

Shenger Gas EPC Contracting Model Process

Early stage of the project

- Shenger Gas (Hong Kong) will conduct a preliminary technical solution design based on the owner's needs, mainly focusing on the selection of cryogenic nitrogen production equipment, such as the demand for nitrogen/oxygen/argon/fixed systems that require nitrogen and oxygen at the same time, and the demand for gas-fixed liquids, etc. Then conduct preliminary investment estimation, energy consumption analysis, site evaluation, technical and economic feasibility analysis, and provide professional advice to the owner. Clarify project scope and boundaries.

- A detailed technical proposal is prepared by the company clarifying the project scope, technical specifications (especially the core parameters of deep-cooled nitrogen production equipment), execution plan, quality and safety standards, acceptance standards, price and payment terms. Conducted technical clarification and business negotiations with the owner to finalize the EPC General Contracting Contract.

Project engineering design phase

- Design a full set of deep cooling air sub-project drawings for customers according to their needs. Our technical team, with thirty years of work experience, according to the customer's personalized needs, from the quality, energy saving, efficiency and other aspects to consider the design drawings for the customer.

Project material procurement stage

- Our company selects, evaluates and manages suppliers efficiently to ensure that the materials and equipment procured meet the quality, cost and progress requirements of the project. The procurement team will also keep abreast of market dynamics in real time and select the most appropriate procurement timing, thereby achieving cost savings.

- For some materials with demanding requirements, we track the production progress (urging) of equipment materials, especially long-cycle equipment and core cryogenic nitrogen refrigeration equipment. Engineers will be dispatched or a third party will be entrusted to conduct factory supervision and factory inspection to ensure that the quality meets the requirements of the specification.

- In addition, a qualified EPC contractor, should have good coordination and communication skills to maintain effective communication with suppliers, project teams as well as other parties involved. Also able to ensure a smooth completion of the procurement and warehousing process when customer projects are behind schedule or when there is a demand for additional early delivery deadlines.

Project production and manufacturing stage

- During the manufacturing phase of the deep-cooled air separation nitrogen project, our experienced technical team started from drawings and their own experience to pursue excellence in manufacturing for each segment. Moreover, during the construction process, the construction quality is strictly controlled to ensure that all construction links meet the design codes and quality standards. We also set up a dedicated quality management team to conduct quality supervision and inspection throughout the process!

- The deep-cooled air sub unit contains a large number of complex equipment and piping systems, and EPC contractors need to have specialized equipment installation and commissioning capabilities to ensure that the equipment is properly installed and commissioned so that it is in optimal working condition. Therefore, our division holds special equipment production permits such as pressure vessels and industrial pipelines.

Project installation and commissioning phase

- In the final installation phase. Our company delegates project managers to be stationed on site for a long time to complete the final installation and commissioning within the time required by the customer!

- Shenger Gas in the construction and installation stage of the deep cooling air sub-project, from the acceptance of civil foundation, equipment hoisting in place, strictly control process pipeline welding, electrical instrumentation installation and system wiring, synchronously promote the construction of equipment cooling layer; After the internal clean assembly is completed, pearl sand filling and sealing is completed, and finally passes pipeline pressure test, system blowing and single-machine test drive, laying the foundation for subsequent bare cold leakage inspection and linkage commissioning.

- After the installation, Shenger Gas organized and dominated the start-up process of the entire air separation device. Start the air compressor, precooling system, purification system, and expander according to strict steps, and gradually cool the distillation tower to establish the distillation working condition. Adjust the operating parameters (pressure, temperature, flow rate) to produce qualified gas incrementally.

Project closing and handover phase

- Shenger Gas will organize and hand over a full set of project completion documents to customers, including: final drawings, design calculations, equipment operation and maintenance manuals, certificates of conformity and inspection reports, material certificates, welding records, non-destructive testing reports, commissioning records, start-up reports, performance evaluation reports, quality documents and safety documents, etc.

- On this basis, we will provide comprehensive system training for the owner’s operation, maintenance and management personnel, and provide complete training information to help customers quickly master the operation and maintenance methods of deep-cooled air sub-devices and deep-cooled nitrogen refrigeration equipment.

- Finally, we will cooperate with the owner to complete the final completion acceptance of the project and sign the completion acceptance certificate. Even after the project is completed, Sener Gas will still provide defect repair and technical support within the contractually agreed warranty period, with regular return visits to ensure long-term stable operation of the air separation equipment.

- Choosing an EPC contractor for your cryogenic air separation project offers numerous advantages. The EPC model provides one-stop general contracting services, encompassing design, procurement, construction, and commissioning. This eliminates the need for the client to coordinate multiple contractors, making project execution more efficient and convenient.

- With the professional management, rich experience and full-process service capabilities of Shenger Gas, customers can significantly improve project execution efficiency, reduce engineering risks, and ensure that the cryogenic air subdivisions and cryogenic nitrogen refrigeration equipment can be put into operation on time and with high quality.