principle

VPSA oxygen production device is based on the self-developed and produced internationally leading level of new high-efficiency lithium-based air separation oxygen production adsorbent PU-8.

Technical Parameters

產氧規模:10~ 20000Nm/h 氧氣純度:21~ 95 % 範圍內可調

製氧能耗:氧純度為90 % 時為0.32~ 0.37KW . h/Nm3

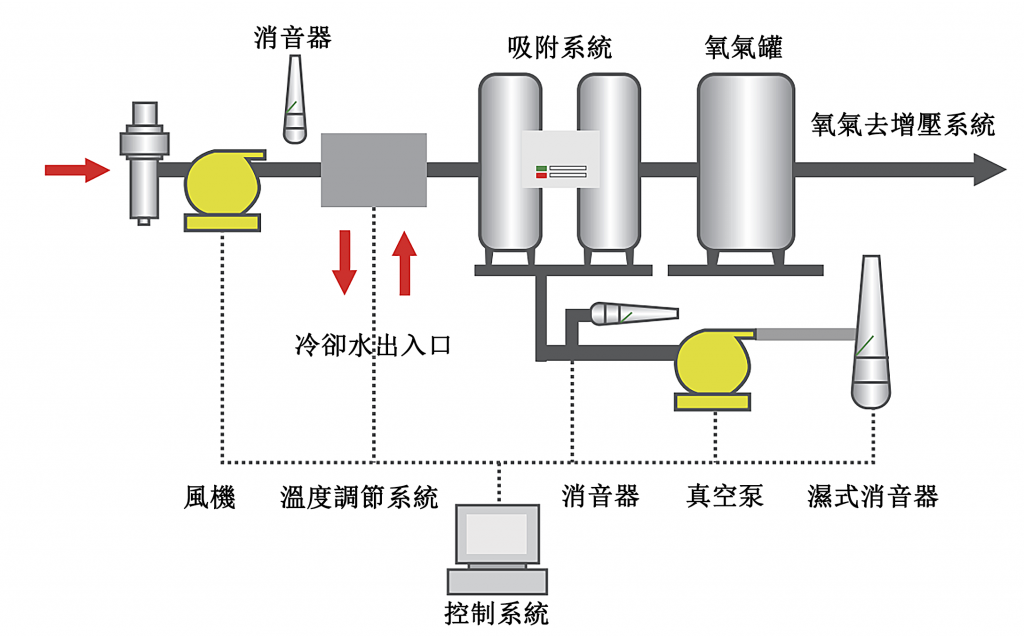

Process

Nitrogen production process

- Purification: VPSA nitrogen production device first filters the air through the filtration device to remove dust and other impurities in the air to avoid entering the blower and affecting the equipment.

- Adsorption: The pretreated air enters a container containing zeolite to remove moisture and carbon dioxide and adsorb nitrogen as oxygen exits through the container. The adsorption process was interrupted before the adsorption capacity of the zeolite was depleted.

- Desorption: Saturated zeolites are regenerated by decompression below the adsorption pressure (i.e., release of adsorbed gases). This is achieved through a dry vacuum pump. The produced exhaust gases are discharged into the atmosphere. In order to maintain the continuous flow of oxygen supply, pressure regulator tanks are installed so the cycle continues.

Features

- The oxygen production has low energy consumption. Compared with similar domestic technologies, the electricity consumption is 10~30% lower.

It is easy to operate, convenient to start and stop, occupies a small area, has low maintenance cost, and low installation and civil construction cost.

The process is advanced, the degree of automation is high, the operation is flexible, and the long-term operation reliability is high.

The fast start-up time is only 10 minutes to obtain the required oxygen purity. Therefore, these devices can be turned on and off depending on the change in oxygen demand.

Fully automated All systems are designed for continuous operation with automatic adjustment of oxygen demand.

Industrial Applications

Oxygen has a wide range of applications in various process processes and in almost all branches of industry.

- 金屬氣體焊接、切割同鎢焊 — 氧氣允許喺焊槍中產生高溫火焰,從而確保高質量同快速嘅工作性能。

金屬工業 — 氧氣喺金屬工業中大量使用,佢有助於提高黑色金屬同有色金屬生產嘅燃燒溫度,並且明顯提高整體工藝效率。

化學同石化工業 — 喺化學同石化工業中,氧氣被廣泛用於氧化原料化學品以回收硝酸、環氧乙烷、環氧丙烷、氯乙烯同其他重要化合物。

養魚 — 喺養魚過程中使用氧氣有助於提高存活率同生育率,並縮短潛伏期。除咗魚類養殖之外,氧氣仲用喺蝦、蟹同貽貝嘅養殖。

玻璃工業 —— 喺玻璃窯爐中,氧氣被有效地用於提高燃燒溫度同改進燃燒過程。