principle

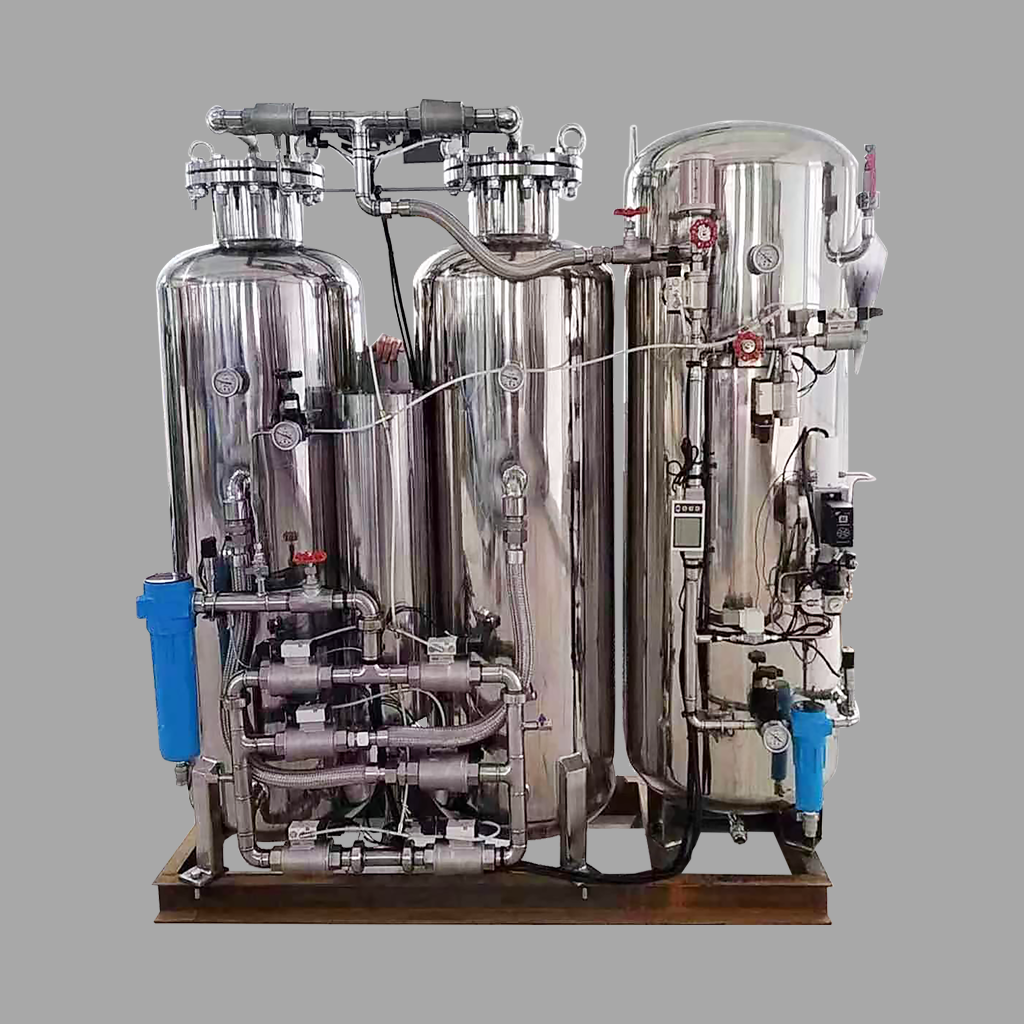

Stainless steel nitrogen maker is equipment that employs carbon molecular sieve as the adsorbent and uses the principle of pressure swing adsorption to obtain nitrogen. Under a certain pressure, using the difference in the amount of adsorption of oxygen and nitrogen in the air on the surface of the carbon molecular sieve, that is, the diffusion adsorption of oxygen by the carbon molecular sieve is far greater than nitrogen, through the programmable control of the opening and closing of the pneumatic valve, A and B two towers alternate cycle, nitrogen production device pressurized adsorption, decompression desorption process, complete the oxygen and nitrogen separation, obtain the required purity of nitrogen.

Technical Parameters

Purity: 97~ 99.999% Material: Stainless steel

Nitrogen pressure: 0.1~ 1.0MPa Dew point temperature: -40°C~ -60°C

Advantages of stainless steel nitrogen generators

The most obvious difference between carbon steel and stainless steel is corrosion resistance, stainless steel nitrogen makers have strong corrosion resistance. Because both carbon steel and stainless steel contain the element of iron, iron oxidizes when exposed to the environment, creating rust. And chromium is added to stainless steel, which causes increased corrosion resistance of stainless steel, thereby making stainless steel more corrosion resistant than carbon steel. Chromium binds to oxygen more easily than iron, and when chromium attaches to oxygen, it forms a chromium oxide layer that is able to protect the steel from degradation, corrosion. Carbon steel has less chromium content, a small amount of chromium cannot form that chromium oxide layer, and oxygen combines with iron, resulting in iron oxide, iron rust. If corrosion resistance is a key factor for you, then a stainless steel nitrogen maker is your go-to equipment.www.shengerhk.com