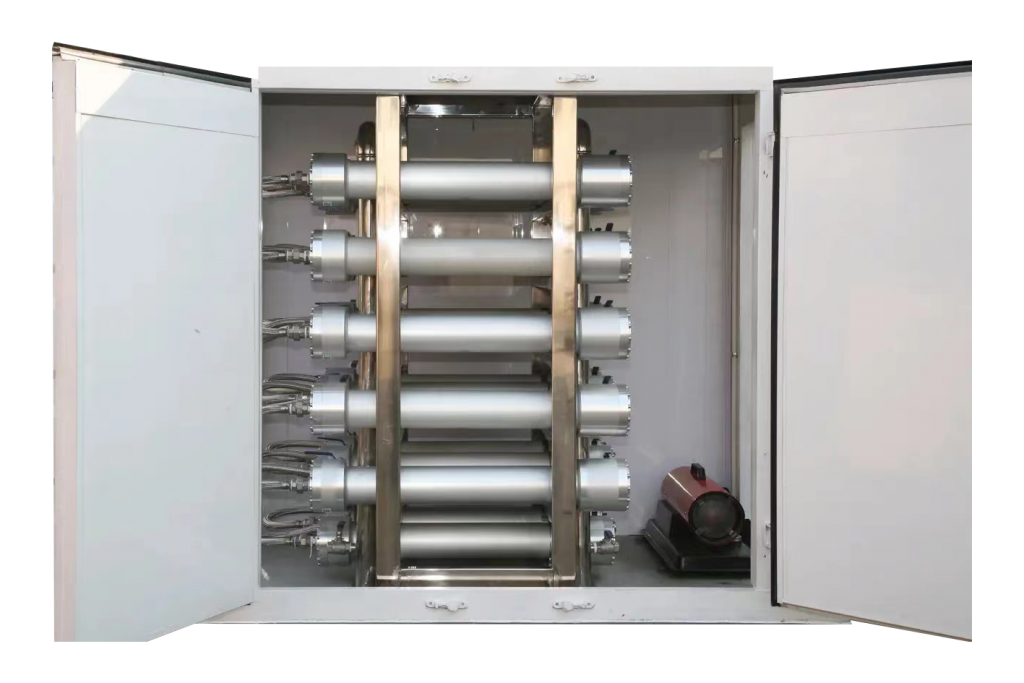

How it works

Membrane separation nitrogen generator technology is based on the different solubility and diffusion coefficients of nitrogen and oxygen in the air in the membrane under the action of pressure difference between the two sides of the membrane.

Technical Parameters

Nitrogen production: 5~3000Nm3/h Nitrogen purity: 95%~99.9% Nitrogen pressure: 0.1~2.0Mpa (adjustable, boostable) Nitrogen dew point: -40°C~-60°C Different gases are separated through gases with different permeation rates

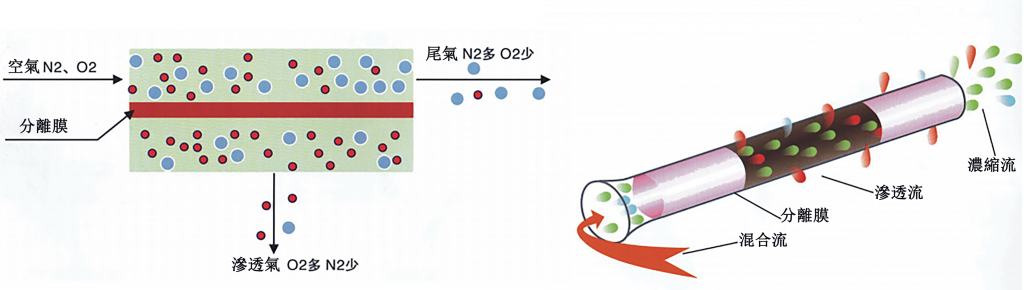

Schematic diagram of membrane separation nitrogen production

Membrane Separation Nitrogen Maker performs nitrogen and oxygen separation through a hollow fiber membrane. Oxygen is a “fast” gas that selectively diffuses through the membrane wall, while the slower nitrogen continues to flow along the interior and smaller portions of the fiber, forming a high-concentration airflow and reaching the outlet of the fiber bundle where it is collected. Oxygen-rich or permeating gases are discharged from the membrane separator at atmospheric pressure. The physical cause of the separation is the difference between the partial pressure of the gas inside the hollow fiber and the external pressure. No drive valves or moving parts are required, and simplicity and reliability underlie the technology, from the installation of the system to the production of nitrogen and its associated maintenance. Membrane generator inlet requires only constant temperature (or even moist) clean compressed air for immediate production. Many nitrogen applications require high purity for inertification or elaborate and accurate purposes (e.g., the food or pharmaceutical industry), and membranes can produce nitrogen with a purity of up to 99.9%.

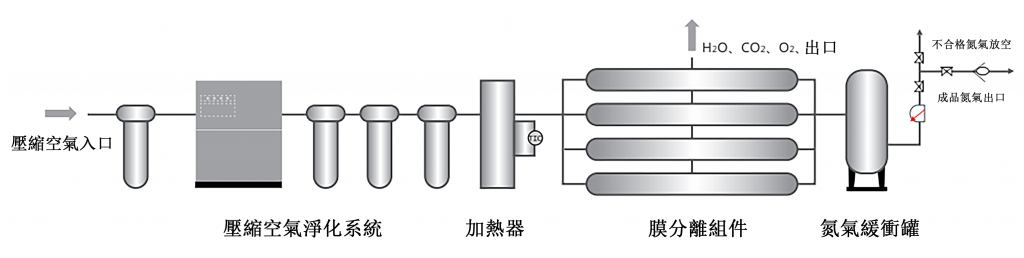

Membrane separation nitrogen generator process

The membrane separation nitrogen maker and the PSA pressure pressure adsorption nitrogen maker have much the same flow, the air is compressed, purified, the nitrogen is separated, and finally in the nitrogen buffer tank. The difference lies in the different ways of separating and removing nitrogen, membrane separation mainly uses central control fiber membranes for nitrogen and oxygen separation. Nitrogen purity is not as high compared to PSA nitrogen generators, generally below 99.9%. Membrane separation nitrogen generators also have their own advantages:

- 操作簡單,運行可靠,自動化程度高,冇運動部件,無需循環切換,滿足長期連續運行要求;

開/停車方便迅速,開機10分鐘左右即可生產合格氮氣:運行能耗低,氮氣純度連續可調;

氣體分離過程冇噪音,冇污染,唔產生有害廢物,產氮潔淨度高;

可通過增加膜組件來擴大系統嘅產氮能力,滿足客戶對唔同氮氣產量嘅需要;

具有膜組進氣品質檢測同保護裝置,確保合格氣體進入膜組件,提高咗膜嘅使用壽命;

整機結構緊湊,安裝方便,佔地面積小適用範圍廣,能抗許多化學污染。