How it works

Nitrogen and hydrogen enter the nitrogen purification device at a fixed flow rate, where it is thoroughly mixed first through an automatic ratio system and a static mixer before entering the catalytic deoxidizer. Under the action of the catalyst, the residual oxygen in nitrogen reacts with hydrogen to produce water (2H2+O2→2H2O), achieving the oxygen removal effect.

The gas is then removed through the water filter to generate moisture and enters the dehydrogenator to remove excess hydrogen;this step can be skipped if the process allows to carry a small amount of hydrogen. Finally, the nitrogen was double dehumidified by chilling and adsorption dryers to obtain dry and stable high-purity nitrogen.

The entire process boasts a high degree of automation and stable operation, making it suitable for industries such as electronics, photovoltaics, metallurgy, chemicals, and food. Shenger Gases (Hong Kong) Co., Ltd. provides one-stop nitrogen purification and EPC solutions, ensuring that gas purity, energy efficiency, and reliability meet international standards.

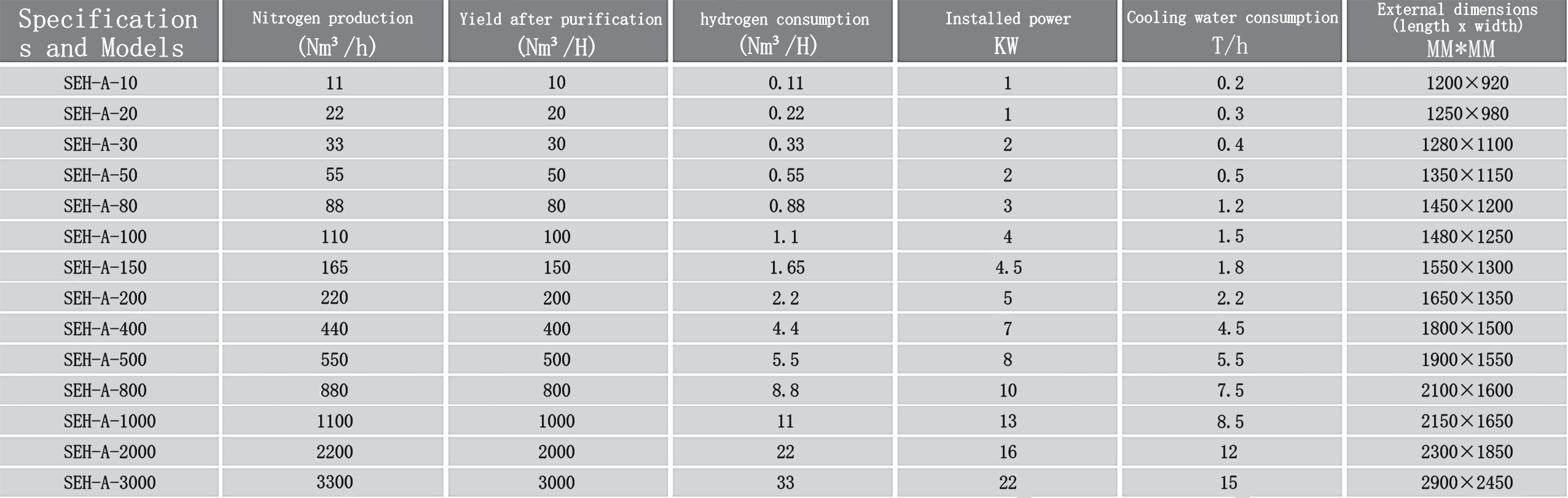

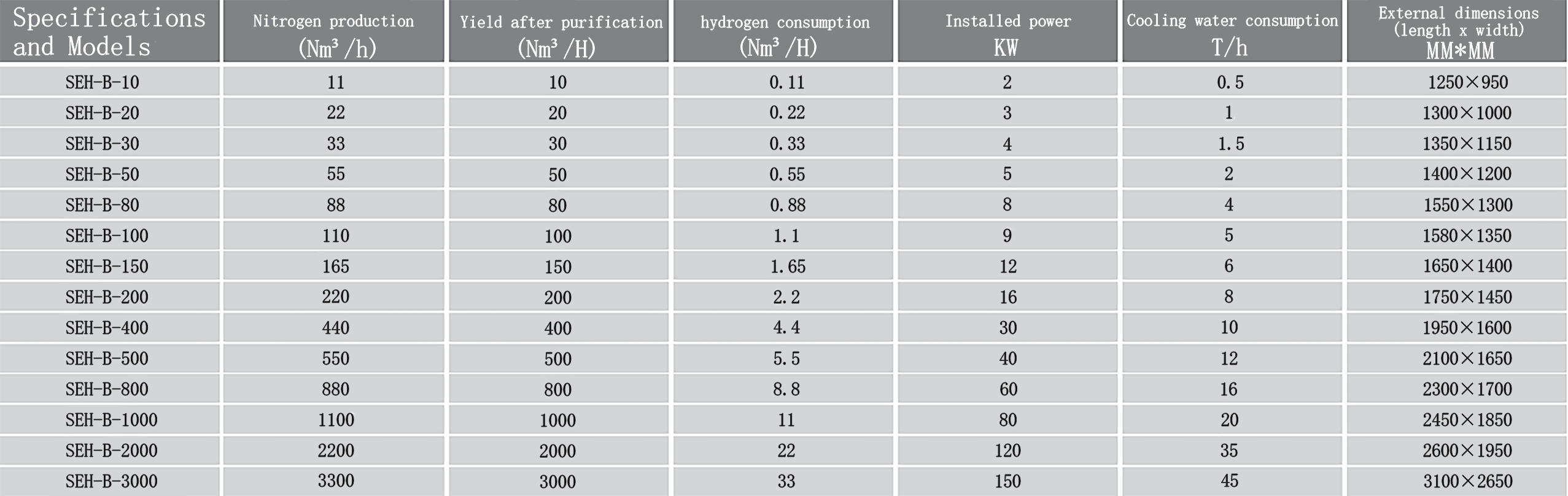

Technical Parameters

Nitrogen output: 10~ 3000Nm/h Nitrogen purity: ≥ 99.9995%

H2 content: ≤ 3PPm Pressure drop: 0.1Mpa

Oxygen content: ≤ 5PPm Nitrogen atmospheric pressure dew point: -60°C

Features

Shenger Gas uses efficient and durable deoxygenation and dehydrogenation catalysts with long life and high stability to ensure long-term stable operation of the system. The deoxygenation reaction can be carried out at room temperature without heating, which greatly reduces energy consumption and operates more energy-saving and environmentally friendly.

The requirements for raw gas are relaxed, and the purity of universal nitrogen can be used in the range of 98% to 99.9%, flexibly adapting to different industry needs. The hydrogen addition purification device features an automatic ammonia-hydrogen rationing system that automatically calculates and precisely controls the amount of hydrogen added based on ammonia flow and purity. The whole process adopts fully automatic control mode, sensitive response, small lag, high adjustment precision.

All electrical components in contact with hydrogen have an explosion-proof design to ensure the equipment is safe and reliable. Nitrogen-hydrogen mixing is accomplished in a static mixer with uniform mixing, high reaction efficiency, and low hydrogen consumption. The system is also equipped with an automatic interlocking deflation function and multiple fault alarm protection mechanisms to further enhance overall safety and stability.

Shenger Gas (Hong Kong) Co., Ltd. is committed to providing holistic solutions for high-purity nitrogen and hydrogen purification systems, with stability, energy saving, and safety at its core, to meet the needs of customers in electronics, chemicals, metallurgy, food and other fields.

Process

Technical Specifications