How it works

SER Heatless Regenerative Adsorption Dryer is designed based on the Pressure Swing Adsorption (PSA) principle, and is used for the deep dehumidification and drying of compressed air.

Under the pressurized condition, the adsorbent inside the adsorption tower removes moisture from the compressed air to achieve a drying effect;

when the system depressurizes, a portion of the already dried compressed air is used for purge regeneration, discharging the moisture from the adsorbent and restoring its adsorption capacity.

The two adsorption towers operate alternately in a cyclic mode, continuously supplying stable and dry compressed air.

Depending on the required dew point temperature (Dew Point), different types of adsorbents can be selected:

common adsorbents include Activated Alumina and Molecular Sieve, etc.

This series of dryers features a simple structure, reliable operation, and easy maintenance, making it especially suitable for industrial gas systems, precision instruments, and automated equipment.

Technical Parameters

Working Pressure: 0.6–1.0 MPa (1.0–3.0 MPa available upon request) Inlet Temperature: 45°C

Outlet Air Dew Point (at atmospheric pressure): –40°C (Activated Alumina), –60°C (Molecular Sieve) Regeneration Air Consumption: ≤12%

Power Supply: AC 220V / 50Hz Pressure Drop: 0.023 MPa

Features

Scientifically Optimized Structural Design

Equipped with an automatic pressurization and pressure equalization process, effectively reducing the impact of airflow on the adsorbent and extending the adsorbent’s service life.

Adopts a flanged filling and discharge port design, making maintenance and desiccant replacement more convenient and efficient.

Optimized flow rate design combined with high-quality adsorbents ensures a stable dew point of the outlet air and reliable drying performance.

The specially designed gas distributor ensures uniform airflow distribution, allowing full contact between the compressed air and the adsorbent, effectively preventing adsorption “dead zones” and “tunnel effects.”

Smart Control System

The whole machine adopts a Siemens PLC controller from Germany and a liquid crystal display (LCD) interface, equipped with touch keys for user-friendly operation.

It can automatically adjust the adsorption and regeneration time according to actual operating conditions, ensuring optimal balance between energy consumption and efficiency.

控制氣流取自吸附塔出口乾燥空氣,避免油氣或水分污染控制閥及氣路,有效防止閥門生銹或堵塞。

High-quality components ensure reliability

The entire system is equipped with high-quality control components and pneumatic valves, featuring quick switching response, long service life, and low maintenance requirements.

The equipment is equipped with a drying and regeneration status indication display function, making the operating status clear and visible.

The above designs ensure the long-term stable operation of the entire system, making it suitable for high-demand industrial gas applications.

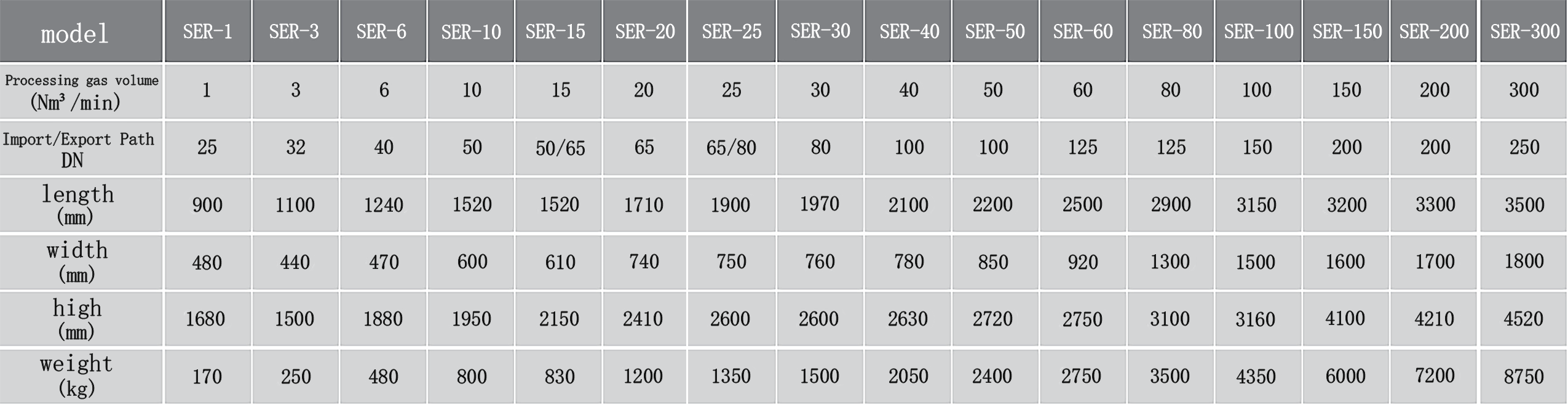

Technical Specifications