Industrial nitrogen generator systems have become a mainstream alternative to delivered liquid nitrogen and high-pressure cylinders in many plants. By bringing nitrogen production inside the fence line, on-site nitrogen gas generation gives engineers direct control over purity, pressure and availability, instead of depending on tanker deliveries and fluctuating contract prices.

For facilities running 24/7 – steel mills, food-packaging lines, electronics factories, chemical and petrochemical plants – industrial nitrogen generator systems are now treated much like a core utility. They are engineered, monitored and optimized in the same way as compressed air, cooling water or steam, with clear performance targets and lifecycle cost models behind them.

Principles of on-site nitrogen gas generation

Most industrial nitrogen generator systems in use today are built around two technologies:

- Pressure swing adsorption (PSA)

- Membrane separation

In both cases, compressed air is first filtered and dried, then fed into a separation module that selectively removes oxygen and trace gases, leaving a nitrogen-rich stream for downstream use.

PSA nitrogen generators use columns filled with carbon molecular sieve (CMS). At elevated pressure, the CMS preferentially adsorbs oxygen, CO₂ and moisture, while nitrogen passes through as product gas. By cycling two (or more) columns out of phase – one adsorbing while the other regenerates at low pressure – the system delivers a continuous nitrogen stream. Modern PSA units can cover a purity range roughly from 95% up to 99.999% nitrogen, depending on bed volume, cycle design and instrumentation. Compressed Air Best Practices+2Atlas Copco+2

Membrane-based on-site nitrogen gas generation relies on bundles of hollow polymer fibers. Gases with higher permeability (oxygen, water vapor, CO₂) pass through the membrane wall faster than nitrogen, so the retentate stream becomes enriched in nitrogen. Membrane systems are mechanically simple, have no moving parts in the separation stage, and respond quickly to load changes. They are typically used for purities up to about 99–99.5% nitrogen, where they offer a good compromise between footprint, complexity and cost. Parker Hannifin Corporation+1

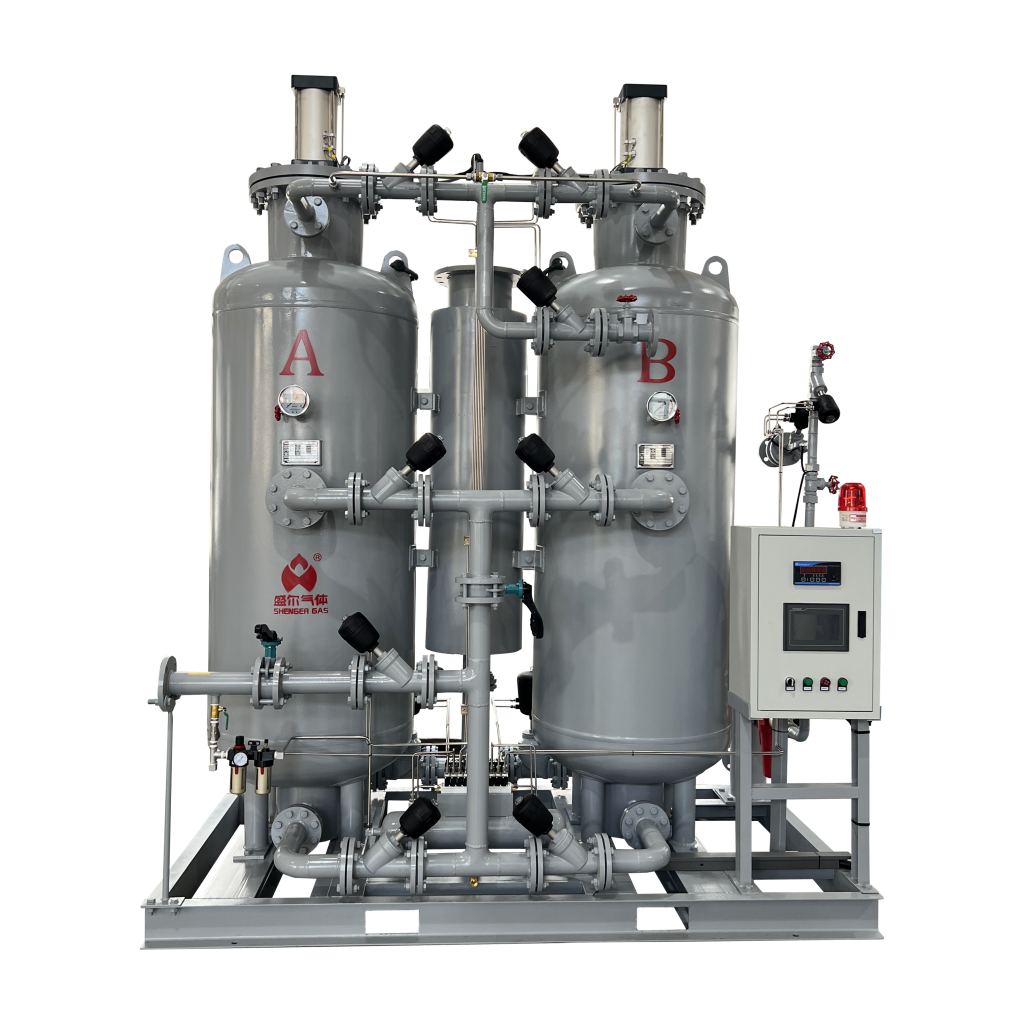

Typical configuration and main components

Although layouts differ by supplier and capacity, most industrial nitrogen generator systems share a similar architecture:

- Feed air supply – An oil-injected or oil-free screw compressor sized for the required nitrogen flow, purity and pressure, with margin for peak demand and future expansion.

- Air treatment line – Cyclone separators, coalescing and particulate filters, and a dryer (refrigerated or desiccant) to reduce inlet dew point and protect the separation stage.

- Nitrogen generation module – One or more PSA skids or membrane racks, often in modular form so capacity can be expanded or isolated for maintenance.

- Product gas handling – Nitrogen buffer vessels, pressure control valves, analyzers and sometimes product boosters for high-pressure users.

- Off-gas handling – Exhaust silencers and vent piping for PSA waste gas, routed to a safe area away from personnel and air intakes.

- Control and monitoring – PLC-based control with oxygen analyzers, flow meters, pressure and dew-point transmitters, and remote connectivity (Modbus, Ethernet, etc.).

From an engineering standpoint, the objective is to integrate on-site nitrogen gas generation into the plant’s existing utility network while maintaining stable pressure, predictable purity and sufficient redundancy to tolerate upsets or planned shutdowns.

Performance parameters and typical ranges

When specifying industrial nitrogen generator systems, engineers usually focus on a small set of performance parameters:

- Nitrogen purity and residual O₂

- Flow rate at normal conditions (Nm³/h or SCFM)

- Delivery pressure at the main header

- Product gas dew point

- Specific energy consumption (kWh per Nm³ of nitrogen delivered)

A typical medium-scale PSA system for industrial use might fall within the ranges below.

Table 1 – Typical technical range for industrial nitrogen generator systems (PSA-based, medium scale)

| Parameter | Typical range |

|---|---|

| Nitrogen purity (vol %) | 95 – 99.999 |

| Residual O₂ content (vol ppm) | ~50 – 50,000 (depending on purity setpoint) |

| Nitrogen flow rate (Nm³/h) | 10 – 500 per skid (higher with multi-skid systems) |

| Delivery pressure (barg) | 4 – 10 (higher with downstream boosters) |

| Product gas dew point (°C) | –40 to –70 |

| Specific energy (kWh/Nm³ N₂) | ~0.2 – 0.6 (including air compression) |

These values are indicative. Actual numbers depend strongly on inlet air temperature, required purity and whether the generator uses a dedicated compressor or shares capacity with a central compressed-air station. Higher purities require more CMS volume and longer cycles, so specific energy and capital cost both climb non-linearly as you add extra “nines” to the specification. Compressed Air Best Practices+1

From a design perspective, it is rarely optimal to specify 99.999% nitrogen for a process that only needs 99% to meet safety and quality requirements; the extra 0.999% can easily double both CAPEX and OPEX.

Compared with bulk nitrogen supply

For many users, the first driver behind industrial nitrogen generator systems is cost. On-site production eliminates:

- Evaporation losses from cryogenic storage tanks

- Residual gas losses in cylinders (“heel” left in each bottle)

- Rental and logistics costs associated with tanks, cylinders and deliveries

Field data from multiple sectors suggest that PSA-based on-site nitrogen gas generation can reduce nitrogen unit cost by roughly 50–90% compared with traditional bulk liquid supply, especially in plants with steady, continuous consumption. Mikropor America

But economics are only part of the story. On-site systems also:

- Decouple production from deliveries – no risk of late trucks or supplier shortages

- Reduce safety exposure – fewer large cryogenic tanks and high-pressure cylinder bundles on site PeakGas+1

- Cut waste and emissions – nitrogen is produced as needed, with no boil-off or off-gassing losses, and fewer transport-related CO₂ emissions 博盈科技+1

For processes where a nitrogen outage would force an emergency shutdown – e.g. continuous annealing lines, some reactors or high-power laser cutting – the security of supply from a well-designed generator is often more valuable than the pure cost advantage.

Application scenarios

Industrial nitrogen generator systems are deployed across a wide range of industries, but the design priorities differ significantly by application.

- Food and beverage packaging

Modified atmosphere packaging (MAP) for snacks, nuts, coffee and ready-to-eat meals typically runs at 98–99.5% nitrogen purity. The main goal is to push oxygen low enough to slow oxidation and microbial growth while maintaining reasonable energy consumption. Compressed Air Best Practices+1 - Electronics and semiconductor manufacturing

Solder reflow ovens, wave soldering lines and many cleanroom processes require 99.99% and above, sometimes up to ultra-high purity nitrogen. In these cases, PSA systems may be combined with polishing stages or supplemented with cylinders for very small ultra-pure consumers. organomation.com+1 - Metal processing and laser cutting

Fiber and CO₂ laser cutting systems often use 99–99.99% nitrogen at relatively high pressure to achieve clean, oxide-free edges. The generator is normally paired with high-pressure boosters and sizeable buffer vessels to handle short, sharp peaks in demand during piercing and thick-plate cutting. - Chemical and petrochemical plants

Large volumes of nitrogen at 95–99% purity are used for inerting, line and vessel purging, blanketing and pressure transfer. Here, engineering focus is on reliability, tie-in philosophy (e.g. to flare systems) and ensuring that nitrogen headers are properly isolated from oxygen service. - Oil and gas operations

Pipeline pigging, tank blanketing and offshore process safety use skid-mounted or containerized on-site nitrogen gas generation packages. These systems must handle harsh environments, limited footprint and constrained maintenance access, so robustness and simplicity become key design criteria. Advanced Gas Technologies

Sizing and integration considerations

In practice, sizing industrial nitrogen generator systems is less about picking a catalogue flow and more about matching the generator closely to real demand and plant constraints. A realistic design workflow usually includes:

- Characterizing demand

Separate base load from variable load and short-term peaks. Where practical, use buffer vessels to absorb peaks instead of oversizing the generator by a large margin. - Choosing purity setpoints

Start from process safety and product quality requirements, not from arbitrary “high purity” targets. Each extra step in purity increases bed volume, specific energy and maintenance cost. - Integration with compressed air

Decide if the generator should have a dedicated air compressor or share a central station. Shared systems save CAPEX but need careful checking for pressure stability and dew-point margins, especially when other large consumers (e.g. instrument air, process air) are on the same header. - Redundancy strategy

For high-criticality users, N+1 or multi-skid modular layouts allow maintenance without stopping production. Some facilities also retain a small bulk tank or cylinder manifold as an emergency back-up, even after switching to on-site nitrogen gas generation as the primary source. - Control, data and optimization

Modern generators expose purity, flow and energy data over standard industrial networks. Feeding these signals into the plant historian allows engineers to correlate nitrogen performance with product quality, energy KPIs and downtime events, and to fine-tune setpoints over time.

Environmental and safety aspects

From a sustainability perspective, on-site nitrogen gas generation eliminates the regular trucking of liquid nitrogen and reduces emissions associated with transport and external cryogenic production. Because nitrogen is generated close to the point of use, there is also less venting and boil-off compared with large bulk tanks.

Safety considerations for industrial nitrogen generator systems are mainly linked to oxygen depletion and pressure:

- Enclosed spaces where nitrogen is produced or used should be assessed for asphyxiation risk and equipped with adequate ventilation and, where needed, oxygen monitors.

- Pressure vessels, filters and pipework must comply with relevant pressure-equipment codes, with regular inspections and maintenance.

- Work procedures should recognize that a nitrogen generator is a live process unit; isolation, lock-out/tag-out and confined-space rules need to be applied accordingly.

Conclusion

For many facilities, industrial nitrogen generator systems have moved from “interesting option” to default choice. By treating on-site nitrogen gas generation as a core utility – engineered with the same rigor as compressed air or power – plants can tune purity, cost, reliability and environmental impact to their own process, instead of inheriting whatever mix of tanker deliveries and cylinder logistics happens to be available. When properly specified, integrated and monitored, these systems become a quiet but critical backbone for safe, efficient operation across food, electronics, metals, chemical and energy industries.