Engineers choose an on-site Nitrogen Generator to replace cylinders and bulk deliveries when they need predictable purity, lower logistics risk, and control over operating cost. Depending on purity and flow, modern systems deliver steady nitrogen for production lines, analytical instruments, and safety-critical inerting. Below you’ll find how it works in practice and what specifications actually matter in five high-value scenarios.

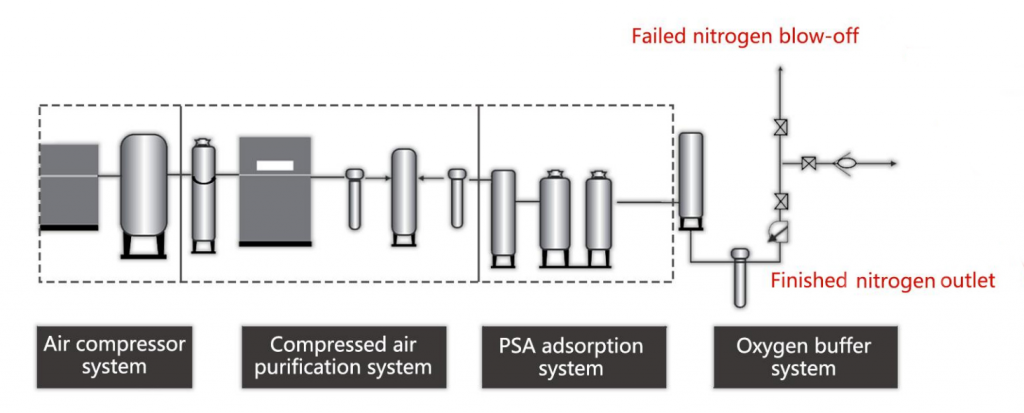

How a Nitrogen Generator works (PSA/Membrane in one minute)

A Nitrogen Generator takes clean, dry compressed air and separates nitrogen on demand. Two mainstream designs are used. PSA (pressure swing adsorption) runs twin adsorber vessels filled with carbon molecular sieve; oxygen and trace gases adsorb under pressure, nitrogen passes, then beds regenerate at low pressure. Membrane systems drive compressed air through hollow fibers; fast-diffusing gases (oxygen, moisture, CO₂) permeate, while nitrogen is retained on the high-pressure side. PSA is favored for higher-purity requirements (to 99.999%), while membranes excel at mid-purity (90–99.9%) with compact hardware and fast turndown. For planning, allow dry air at ≤–40 °C dew point, oil carryover within the generator’s spec, and stable header pressure.

Use Case 1 — Laser Cutting (assist gas)

A Nitrogen Generator for fiber/CO₂ laser cutting must deliver high purity and pressure to keep cut edges bright and oxide-free, especially on stainless steel and aluminum. Typical needs:

- Purity: 99.95–99.999% (material and thickness dependent).

- Flow: ~10–300 Nm³/h per laser, scaling with nozzle diameter, kerf width, and plate thickness.

- Pressure: 12–22 bar for most jobs; thicker stainless may push higher.

- Dew point: ≤–40 °C recommended, ≤–60 °C ideal for consistency.

PSA systems paired with a high-pressure booster (or liquid buffer + ambient vaporizer) are common. For mixed shops, a staged approach works: base load from PSA at 99.95–99.99%, with a polishing skid or storage to meet peak cutting windows.

Use Case 2 — Food Packaging (MAP)

A Nitrogen Generator in modified-atmosphere packaging displaces oxygen to slow oxidation, moisture migration, and microbial growth.

- Purity: 99–99.9% depending on product; snacks may accept lower oxygen, dairy/meat trend higher.

- Flow: ~5–100 Nm³/h per line, driven by pouch volume, cycles/min, and residual O₂ targets.

- Pressure: 5–8 bar to feed gas mixers/flow wrappers; ensure stable regulator response.

- Dew point: ≤–40 °C to avoid condensation in valves and hoses.

Membranes serve mid-purity lines efficiently with excellent turndown. Where lines share a manifold, PSA plus buffer tanks smooth transients at shift changes.

Use Case 3 — Laboratories (LC/MS, GC, gloveboxes)

A Nitrogen Generator in labs supports instruments and atmospheres that are intolerant to oxygen or water.

- Purity: 99.5–99.999% depending on instrument; LC/MS typically 98–99.5% for nebulizer gas when paired with dry air, while some applications need UHP.

- Flow: ~10–60 L/min per instrument (≈0.6–3.6 Nm³/h).

- Pressure: 6–8 bar (≈90–120 psi) stable, with low pulsation and quiet acoustics.

- Dew point: ≤–60 °C for UHP and glovebox feeds.

Rack-mount PSA is popular for UHP. Noise, heat rejection, and filter change intervals matter in enclosed labs; specify service clearances and quick-change filter kits.

Use Case 4 — Electronics/SMT Reflow & Wave Solder

In reflow ovens and wave solder machines, a Nitrogen Generator reduces dross and improves wetting, enabling tighter process windows.

- Purity: 99.9–99.99%; in practice many ovens target O₂ < 1000 ppm, high-reliability lines < 100 ppm.

- Flow: ~20–200 Nm³/h based on oven volume, leakage, and exhaust rates.

- Pressure: 2–6 bar distribution; keep header drops < 0.5 bar at peak.

- Dew point: ≤–60 °C to minimize flux interactions and residue.

Inline oxygen analyzers with closed-loop flow control save power by trimming nitrogen to the ppm setpoint rather than running fixed high flows.

Use Case 5 — Inerting & Corrosion Protection (tanks, pipelines, purging)

A plant-wide Nitrogen Generator provides blanket gas for product tanks, pipeline purging, and catalyst change-outs.

- Purity: 95–99.9% depending on LEL margins and product sensitivity; many hydrocarbon tanks run 95–98%.

- Flow: highly variable: 5–500 Nm³/h normal, 1000+ Nm³/h during purge events.

- Pressure: 2–8 bar manifold, with local regulators at blanketing valves.

- Dew point: ≤–40 °C; colder for hygroscopic products.

For sporadic high-flow purges, consider a hybrid: PSA sized for base blanket plus a liquid nitrogen connection or rental booster for turnarounds.

Power, purity, and the cost balance

Energy is mainly the air compressor’s burden. For planning:

- Membrane systems (mid-purity) often run ~0.18–0.35 kWh/Nm³ at ~95–99% N₂.

- PSA systems trend ~0.28–0.60 kWh/Nm³ as purity climbs to 99.9–99.999%.

- Higher delivery pressure raises kWh/Nm³; so does lower allowable O₂-in-N₂.

Right-size the compressor (or use VSD) and keep pressure losses low. Dryers and filters should match the generator’s spec; oversizing filtration without monitoring differential pressure is a common hidden energy penalty.

Selection and sizing checklist

To keep scopes tight and quotes comparable, anchor selections to measurable requirements. A Nitrogen Generator should be specified with:

- Purity at delivery point (e.g., 99.99% N₂, O₂ ≤ 100 ppm) and verification method (in-line sensor location, calibration interval).

- Flow profile: average, peak, duration (e.g., laser ramp-ups), and simultaneity across lines.

- Pressure at point of use and allowable drop across piping (kPa or bar), including valves and quick-connects.

- Dew point at pressure (°C) and any limits on oil aerosols/particles (ISO 8573 classes).

- Noise/footprint/heat for labs and cleanrooms; for shops, ventilation around the compressor skid.

- Maintenance windows: adsorbent life, filter change hours, valve cycle counts, and spare parts policy.

- Controls and telemetry: O₂ analyzer range/ppm accuracy, data logging, remote alarms, and turndown control strategy.

Plain-text technical table (spec ranges by application)

Table A — Application Requirements and Typical Generator/Utility Specs

Use Case Purity (N2) Flow per Line Pressure Dew Point Notes

———————- —————— ————————- —————- —————- ———————————————

Laser Cutting 99.95–99.999% 10–300 Nm3/h 12–22 bar ≤ –40 °C (–60 best) Assist gas; consider booster or LOX buffer

Food Packaging (MAP) 99–99.9% 5–100 Nm3/h 5–8 bar ≤ –40 °C May blend with CO2; steady header is key

Laboratories (LC/MS/GC) 99.5–99.999% 10–60 L/min (0.6–3.6 Nm3/h) 6–8 bar ≤ –60 °C Rack mount; quiet, low pulsation, UHP filters

Electronics/SMT Reflow 99.9–99.99% 20–200 Nm3/h 2–6 bar ≤ –60 °C Control to ppm-O2 setpoint to save N2/power

Inerting/Blanketing 95–99.9% 5–500 Nm3/h (1000+ purge) 2–8 bar ≤ –40 °C Base + surge planning; tie-in for turnarounds

Typical Generator/Utility Envelope (for scoping)

Table A — Application Requirements and Typical Generator/Utility Specs

Use Case Purity (N2) Flow per Line Pressure Dew Point Notes

———————- —————— ————————- —————- —————- ———————————————

Laser Cutting 99.95–99.999% 10–300 Nm3/h 12–22 bar ≤ –40 °C (–60 best) Assist gas; consider booster or LOX buffer

Food Packaging (MAP) 99–99.9% 5–100 Nm3/h 5–8 bar ≤ –40 °C May blend with CO2; steady header is key

Laboratories (LC/MS/GC) 99.5–99.999% 10–60 L/min (0.6–3.6 Nm3/h) 6–8 bar ≤ –60 °C Rack mount; quiet, low pulsation, UHP filters

Electronics/SMT Reflow 99.9–99.99% 20–200 Nm3/h 2–6 bar ≤ –60 °C Control to ppm-O2 setpoint to save N2/power

Inerting/Blanketing 95–99.9% 5–500 Nm3/h (1000+ purge) 2–8 bar ≤ –40 °C Base + surge planning; tie-in for turnarounds

Typical Generator/Utility Envelope (for scoping)

Table A — Application Requirements and Typical Generator/Utility Specs

Use Case Purity (N2) Flow per Line Pressure Dew Point Notes

———————- —————— ————————- —————- —————- ———————————————

Laser Cutting 99.95–99.999% 10–300 Nm3/h 12–22 bar ≤ –40 °C (–60 best) Assist gas; consider booster or LOX buffer

Food Packaging (MAP) 99–99.9% 5–100 Nm3/h 5–8 bar ≤ –40 °C May blend with CO2; steady header is key

Laboratories (LC/MS/GC) 99.5–99.999% 10–60 L/min (0.6–3.6 Nm3/h) 6–8 bar ≤ –60 °C Rack mount; quiet, low pulsation, UHP filters

Electronics/SMT Reflow 99.9–99.99% 20–200 Nm3/h 2–6 bar ≤ –60 °C Control to ppm-O2 setpoint to save N2/power

Inerting/Blanketing 95–99.9% 5–500 Nm3/h (1000+ purge) 2–8 bar ≤ –40 °C Base + surge planning; tie-in for turnarounds

Typical Generator/Utility Envelope (for scoping)

| Use Case | Purity (N₂) | Flow per Line | Pressure | Dew Point | Notes |

|---|---|---|---|---|---|

| Laser Cutting | 99.95–99.999% | 10–300 Nm³/h | 12–22 bar | ≤ –40 °C (–60 best) | Assist gas; consider booster or LOX buffer |

| Food Packaging (MAP) | 99–99.9% | 5–100 Nm³/h | 5–8 bar | ≤ –40 °C | May blend with CO₂; steady header is key |

| Laboratories (LC/MS/GC) | 99.5–99.999% | 10–60 L/min (0.6–3.6 Nm³/h) | 6–8 bar | ≤ –60 °C | Rack mount; quiet, low pulsation, UHP filters |

| Electronics/SMT Reflow | 99.9–99.99% | 20–200 Nm³/h | 2–6 bar | ≤ –60 °C | Control to ppm O₂ setpoint to save N₂/power |

| Inerting/Blanketing | 95–99.9% | 5–500 Nm³/h (1000+ purge) | 2–8 bar | ≤ –40 °C | Base + surge planning; tie-in for turnarounds |

Implementation notes that prevent surprises

- Buffering: For cutting shops, a high-pressure receiver smooths rapid assist-gas swings. For MAP, a modest low-pressure buffer avoids mixer starvation during film roll changes.

- Analyzer placement: Measure oxygen where it matters—after the point-of-use pressure controller for ovens, at the spray nozzle manifold for lasers, and at the packaging gas mixer outlet for MAP.

- Filtration: Specify coalescing + particulate + optional catalyst stages by ISO 8573 classes, and record differential pressure at commissioning so energy drift can be caught early.

- Controls: Closed-loop purity control can trim compressor load at nights and during idle; it’s often the fastest payback besides fixing leaks.

- Serviceability: Swing-out filter banks, front-access valves, and a clear BOM for adsorbents/filters keep MTTR low—plan these at RFQ time, not after delivery.

Well-scoped projects routinely meet target purity and ppm oxygen while cutting kWh/Nm³ over the first six months as leaks are fixed and setpoints are tuned. With correct air preparation and controls, a Nitrogen Generator becomes a quiet utility that stays out of the way—until a production ramp proves why on-site gas was worth doing in the first place.